Astec tubes are known for manufacturing and supplying the highest quality of Inconel forged fittings. The pipe fittings that we produce are supplied to various clients according to their demands for different dimensions. The pipe fittings made of Inconel alloy has excellent heat and corrosion resistance. It is due to the use of iron, chromium, and nickel alloy. The fittings are desirable in the application where the need to change the diameter or bore, fluid flow, and branching off the pipes in tubing and piping system is required. There are two different types ofInconel/incoloy forged fittings available- socket weld and threaded fittings.

Inconel / Incoloy Forged Fittings Manufacturer

Inconel Forged Fittings, Incoloy Forged Fittings, ASTM B564 Incoloy Forged Fittings, Inconel® Socketweld Fittings, Inconel Alloy Threaded Fittings, Incoloy Alloy Forged Fittings, Inconel Forged Fittings, Inconel Screwed Fittings Suppliers in Mumbai, India.

Table Of Content

And due to their good corrosion resistance, stability, heat resistance, and high-temperature stability these are used in construction and processing industries. Henceforth, we manufacture various forged fittings type such as Inconel nipple branch forged fitting, lateral tee forged fitting, Inconel reducer fittings, and more. More fittings are also produced at Astec tubes. These are forged full couplings, 90-degree elbow outlet, threaded reducer fittings, forged lateral tee, forged boss fittings, forged reducing cross, nipple branch outlet, and more.

We also produce incoloy forged fittings because of their ease in fabrication fittings. It allows the use of fittings at elevated temperature, aggressive corrosion forms, and in aqueous environments. In such environments, fitting resist crevice, pitting corrosion, stress corrosion cracking, and more caused by the use of acetic acids, nitric, organic acids, inorganic, chlorine, and sulfur. On the other hand, the Inconel fittings are also protective from surface corrosive attack due to their ability to form a thick and stable layer of oxide. Also, the use of Inconel in fittings makes them applicable in high pressure and temperature applications. Henceforth, both of these alloys are called as superalloy as they can perform under extreme industrial conditions.

Inconel Threaded Forged Fittings, Inconel Forged Cross, Inconel Alloy Full Coupling, Incoloy Forged 90 Deg Elbow, Inconel® Threaded Plug, Incoloy Alloy Socketweld Bushing, Incoloy Forged Equal Tee, ASME SB 564 Alloy Socket-Weld End Cap, Inconel Socketweld 90 Deg. Elbow, Inconel Swedge Nipple, ANSI B16.11 Inconel Threaded Forged Fittings, Incoloy Alloy Industrial Forged Fittings Manufacturer in India.

The forged fittings are however well tested in our testing units. They undergo tests under the supervision of experts. The tests that we perform on the fittings are- Rockwell hardness test, flaring and flattening test, micro and macro test, ultrasonic test, positive material identification test, mechanical test, intergranular corrosion test, and more. Besides this, we also do mandatory packaging for shipping them in good conditions.

Inconel/Incoloy Forged Elbow

Inconel/Incoloy Forged Tee

Inconel/Incoloy Forged Cross

Inconel/Incoloy Forged Coupling

Inconel/Incoloy Forged Plug

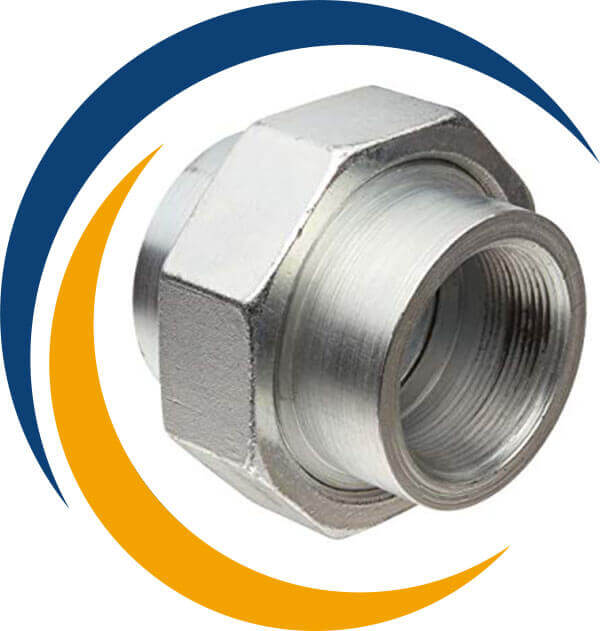

Inconel/Incoloy Forged Union

Inconel/Incoloy Forged Pipe Nipple

Inconel/Incoloy Forged Bushing

Inconel/Incoloy Forged End Cap

Types of Inconel-Incoloy Socketweld/Screwed/Threaded Fittings

Incoloy Socketweld 45 Deg Elbow

Inconel Screwed Equal Elbow

Incoloy Equal Forged Tee

Inconel Alloy Threaded Cross

ANSI B16.11 Inconel Socket-Weld Elbow

Incoloy Pipe Nipples Exporter

Inconel Forged Fittings Dealer

Incoloy Forged Fittings

Incoloy Reducing Coupling

Inconel Alloy Half Coupling

Inconel Forged Pipe Cap Supplier

NCF Socketweld End Cap

Incoloy Threaded Fittings

Incoloy Square Plug

ASME SB 564 Inconel Socketweld Plug

Threaded Fittings

Incoloy Forged Threaded Fittings

Incoloy Socket Weld Cap Manufacturer

Inconel Pipe Union

Incoloy Alloy 90 deg. Elbow Stockist

Inconel Forged Fittings Stockholder

ASTM B564 Inconel Socket Weld Fittings

Incoloy Reducing Cross Fittings

Inconel Alloy Forged Fittings

Manufacturing Standards of Inconel/Incoloy Forged Fittings Manufacturers in India & Globally

| ASME B16.11 | Factory-Made Wrought Socketweld Fittings | Inconel Alloy Forged Screwed Elbows, Street Elbow, Inconel Screwed Unequal Tee,Incoloy Alloy Straight Tee, Inconel Alloy Reducing Coupling, Inconel Hex Plug, Forged Straight Tees, Socket Weld Pipe Cap, Forged Pipe Cap, Equal Crossess, Inconel Alloy Threaded Bushing, Inconel Screwed Caps, Swedge Nipples |

| MSS-SP-79 | standard Practice covers ratings, tolerances, finish, dimensions, marking and material requirements for socket-welding | Incoloy Alloy Barrel Nipples, Incoloy Alloy Forged Threaded Boss,Incoloy Alloy Forged Hex Head Bull Plugs |

| MSS-SP-83 | Forged and Fabricated Socket-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Inconel Alloy High Quality Socket weld 90° Elbow, Straight and Reducing-on-the-Tees,Inconel Alloy Forged 45° Short Radius Elbow, Inconel caps, 3000LB Socket Weld Cross |

| MSS-SP-95 | Integrally Reinforced Forged Fittings – Socket Welding, Threaded, and Buttwelding Ends | Incoloy Socket weld Long Radius 90 Degree Elbows, Reducing Nipple, Socketweld Bushing, Threaded Plug, End Pipe caps, Incoloy Alloy Coupling |

Inconel-Incoloy Socketweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM B564 Inconel-Incoloy Alloy Forged Fittings

Standard : ASTM B564 / ASME SB564

Dimensions : ASME/ANSI 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size : 1/8" NB to 4" NB

Type : Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure : Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.