Astec Tubes is one of the best manufacturers and suppliers of the wide ranges of Monel Forged Fittings. We are providing the superior quality of the forged fittings to both the commercial and international clients. On the other hand, the forged fittings are available in many specifications which is the reason that the forged fittings are used in the industrial application. Some of the specifications in which the forged fittings are available are surface finish, dimensions, toughness, end finish, sizes, and shapes. The forged fittings are also available in the national and international quality standards.

Monel Forged Fittings Manufacturer

ASTM B564 Monel Forged Fittings, Monel Alloy Threaded Fittings, ANSI B16.11 Monel Threaded Forged Fittings, Monel® Forged Fittings, Monel Alloy Socketweld Fittings, Monel Screwed Fittings Suppliers in Mumbai, India.

Forged fittings are the pipe fittings which usually come in the two types such as socket weld fittings and threaded fittings. However, the fittings are used in the piping and plumbing systems which are used to change the flow of work in the industries. The fittings are available is having high dimensional accuracy and also smooth finish. Monel Forged Fittings is having many alloying elements with which it is used in high-temperature applications. The forged fittings are used mostly in the industries which are working in a high-temperature environment. Some of the industries which are using the wide ranges of the forged fittings are pulp and paper, gas and oil, petrochemicals, pharmaceuticals, and others.

On the other hand, this is because of the properties which the Monel Forged Fittings is having. Some of the properties which are there in the forged fittings are corrosion resistance, crevice corrosion resistance, and pitting corrosion resistance. These properties are there with the presence of the nickel and chromium content. In the same way, there are many other elements that are there in the alloy present in manufacturing the forged fittings. Other properties that are there in the forged fittings are great ductility, durability, high tensile strength, weldability, machinability, and stability in the elevated temperatures.

Monel Threaded Forged Fittings, ANSI B16.11 Monel Threaded Forged Fittings, Monel Forged Equal Tee, Monel Socketweld Bushing, ASME SB 564 Monel Socket-Weld End Cap, Monel Alloy Forged Cross, Monel Socketweld 90 Deg. Elbow, Monel Alloy Full Coupling, Monel Forged 90 Deg Elbow, Monel Threaded Plug, Monel Swedge Nipple, Monel Alloy Industrial Forged Fittings Manufacturer in India.

Monel Forged Fittings is moving through several materials testing before delivering the forged fittings to the clients. Some of the tests which are performed are hardness, hydrostatic, ultrasonic, positive material identification, and others. This is done to ensure the clients that they are provided with the best quality of the forged fittings. Packaging of the same is done as per the expectations of the clients.

Monel Forged Elbow

Monel Forged Tee

Monel Forged Cross

Monel Forged Coupling

Monel Forged Plug

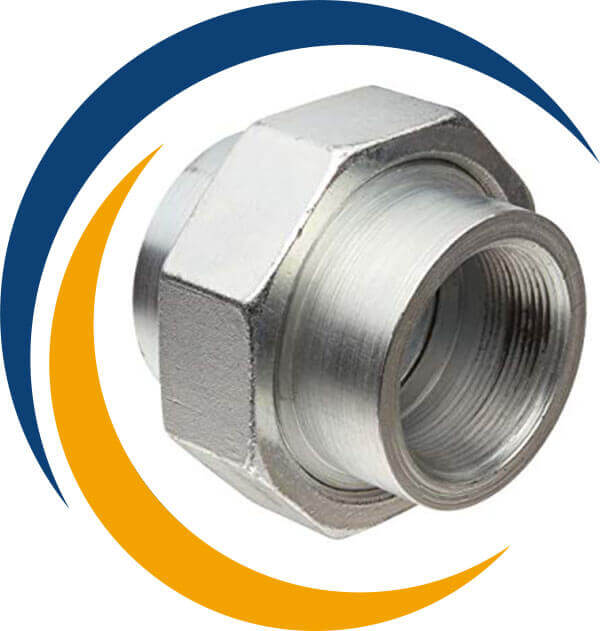

Monel Forged Union

Monel Forged Pipe Nipple

Monel Forged Bushing

Monel Forged End Cap

Types of Monel Alloy Socketweld/Screwed/Threaded Fittings

Monel Socketweld 45 Deg Elbow

Monel Screwed Equal Elbow

Monel Alloy Equal Forged Tee

Monel Alloy Threaded Cross

ANSI B16.11 Monel Socket-Weld Elbow

Monel Pipe Nipples Exporter

Monel Forged Fittings Dealer

Monel Alloy Forged Fittings

Monel Reducing Coupling

Monel Half Coupling

Monel Forged Pipe Cap Supplier

Monel Socketweld End Cap

Monel Threaded Fittings

Monel Square Plug

ASME SB 564 Monel Socketweld Plug

Monel Threaded Fittings

Monel Forged Threaded Fittings

Monel Socket Weld Cap Manufacturer

Monel Alloy Pipe Union

Monel 90 deg. Elbow Stockist

Monel Forged Fittings Stockholder

ASTM B564 Monel Socket Weld Fittings

Monel Reducing Cross Fittings

ANSI 16.11 Monel Forged Fittings

Manufacturing Standards of Monel Forged Fittings Manufacturers in India & Globally

| ASME B16.11 | Factory-Made Wrought Socketweld Fittings | Monel Forged Screwed Elbows, Street Elbow, Monel Screwed Unequal Tee, Steel Straight Tee, Monel Reducing Coupling, Monel Hex Plug, Forged Straight Tees, Socket Weld Pipe Cap, Forged Pipe Cap, Equal Crossess, Monel Threaded Bushing, Monel Screwed Caps, Swedge Nipples |

| MSS-SP-79 | standard Practice covers ratings, tolerances, finish, dimensions, marking and material requirements for socket-welding | Monel Barrel Nipples, Monel Forged Threaded Boss, Monel Forged Hex Head Bull Plugs |

| MSS-SP-83 | Forged and Fabricated Socket-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Monel High Quality Socket weld 90° Elbow, Straight and Reducing-on-the-Tees, Forged 45° Short Radius Elbow, Monel caps, 3000LB Socket Weld Cross |

| MSS-SP-95 | Integrally Reinforced Forged Fittings – Socket Welding, Threaded, and Buttwelding Ends | Monel Socket weld Long Radius 90 Degree Elbows, Reducing Nipple, Socketweld Bushing, Threaded Plug, End Pipe caps, Monel Coupling |

Monel Socketweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM B564 Monel Alloy Forged Fittings

Standard : ASTM B564 / ASME SB564

Dimensions : ASME/ANSI 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size : 1/8" NB to 4" NB

Type : Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure : Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.