Astec Tubes produce and supplies the highest quality of Inconel 625 Forged Fittings in diverse specifications and dimensions. We offer a wide range of fittings to the clients for various applications. We offer them in both standard and customized standards.

Inconel 625 Forged Fittings Manufacturer

Inconel® 625 Socketweld Fittings, Alloy 625 Forged Fittings, ASTM B564 625 Inconel Forged Fittings, Inconel Alloy 625 Threaded Fittings, Inconel 625 Forged Fittings, Inconel 2.4856 Forged Fittings, Inconel UNS N06625 Forged Fittings, Inconel 625 Screwed Fittings Suppliers in Mumbai, India.

Table Of Content

What is Inconel 625 Forged Fittings

Specification of ASTM B564 625 Inconel Forged Fittings

ANSI B16.11 Available Types of Alloy 625 Forged Fittings

ASTM B564 Alloy 625 Threaded Fittings Equivalent Grades

Inconel Alloy 625 Threaded Fittings Chemical Composition

Inconel 625 Socketweld Fittings Mechanical Properties

Types of Inconel 625 Socketweld Fittings

The connection between two pipes or diverting the fluid direction is possible due to the fittings. However, there are different range of fittings such as elbow, union, cross, couplings, reducer, concentric reducer, eccentric reducer, adapter, and connector. Elbow provides a change in 45 or 90 degrees to the fluid inside the pipes. However, elbows are used for connecting the same diameter of pipes. And to connect the different sizes of pipes, the reducer is used. On the other hand, the coupling is used for connecting the broken pipes. However, the slip coupling is used to connect long length pipes whereas compression coupling connects the broken pipe of smaller lengths. The fittings are capable of providing a safe connection to the pipes. Therefore, they are used in industries such as chemical processing, food processing, marine industries, petrochemical, pharmaceuticals, boiler and furnace, transportation and pumping systems.

The Inconel 625 is a niobium, molybdenum, and chromium alloy. This elemental combination infuses serious demanding properties to the fittings. Therefore, our fittings can work under severe high temperature, oxidation, carburization, and corrosive environments. They are however widely used in seawater applications because they are free from local attacks. Their high corrosion and fatigue strength is also an impressive quality. Their use in advanced reactors is possible due to their strength to work under elevated temperatures such as 1200-1400 degrees Fahrenheit.

Inconel N06625 Threaded Forged Fittings, 625 Inconel Forged Equal Tee, 625 Inconel Forged Cross, 625 Inconel Socketweld 90 Deg. Elbow, ASME SB 564 Alloy 625 Socket-Weld End Cap, Inconel Alloy 2.4856 Socketweld Bushing, Inconel® 625 Threaded Plug, Inconel Alloy 625 Full Coupling, Inconel 625 Forged 90 Deg Elbow, NCF 625 Swedge Nipple, ANSI B16.11 Inconel 625 Threaded Forged Fittings, Inconel Alloy 625 Industrial Forged Fittings Manufacturer in India.

The use of Inconel 625 alloy makes them further applicable in industries. The alloy exhibits qualities due to which they are widely used. The alloy exhibits corrosion resistance, heat resistance, high strength, tensile strength, and more. The corrosion resistance is important when working in acidic, aqueous, corrosive, and marine environments. These environments cause crevice, pitting, oxidation, stress corrosion cracking, and more. However, the Inconel 625 Forged Fittings are capable of resisting these attacks. Moreover, they are good to use in elevated temperature and pressure as well. Therefore, our fittings are widely used in all the above industries.

Inconel 625 Forged Elbow

Inconel 625 Forged Tee

Inconel 625 Forged Cross

Inconel 625 Forged Coupling

Inconel 625 Forged Plug

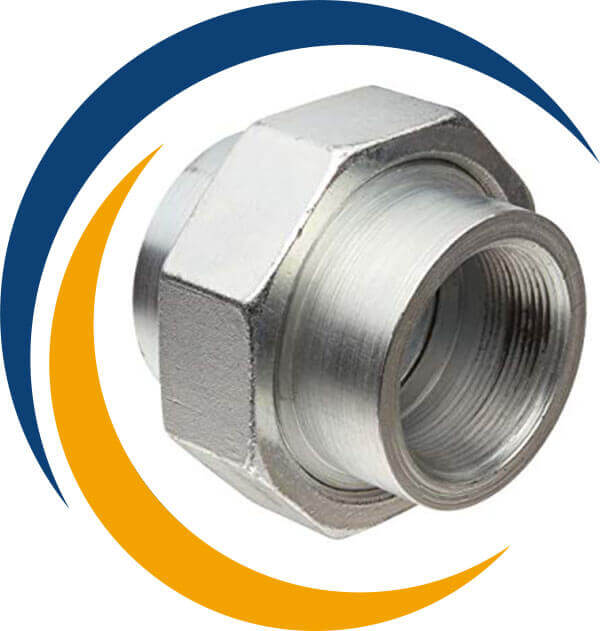

Inconel 625 Forged Union

Inconel 625 Forged Pipe Nipple

Inconel 625 Forged Bushing

Inconel 625 Forged End Cap

Inconel 625 Threaded Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

ASTM B564 Inconel 625 Threaded Forged Fittings Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | - | 5.0 max | 58.0 min | 20.0 - 23.0 |

ANSI B16.11 Inconel 625 Socketweld Fittings Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000, MPa – 930 | Psi – 75,000, MPa – 517 | 42.5 % |

Types of Inconel 625 Socketweld/Screwed/Threaded Fittings

UNS N06625 Socketweld 45 Deg Elbow

Inconel 625 Screwed Equal Elbow

Inconel 625 Equal Forged Tee

Inconel Alloy 2.4856 Threaded Cross

ANSI B16.11 Inconel Alloy 625 Socket-Weld Elbow

Inconel 625 Pipe Nipples Exporter

Inconel 2.4856 Forged Fittings Dealer

Inconel N06625 Forged Fittings

UNS N06625 Reducing Coupling

Inconel Alloy 2.4856 Half Coupling

Inconel 625 Forged Pipe Cap Supplier

NCF 625 Socketweld End Cap

UNS N06625 Threaded Fittings

Inconel 625 Square Plug

ASME SB 564 Inconel 625 Socketweld Plug

2.4856 Threaded Fittings

UNS N06625 Forged Threaded Fittings

Inconel 625 Socket Weld Cap Manufacturer

Inconel 625 Pipe Union

Inconel Alloy 625 90 deg. Elbow Stockist

NCF 625 Forged Fittings Stockholder

ASTM B564 Inconel 625 Socket Weld Fittings

Inconel 625 Reducing Cross Fittings

Alloy 625 Inconel Forged Fittings

Manufacturing Standards of Inconel 625 Forged Fittings Manufacturers in India & Globally

| ASME B16.11 | Factory-Made Wrought Socketweld Fittings | 625 Inconel Alloy Forged Screwed Elbows, Street Elbow, 625 Inconel Screwed Unequal Tee, 625 Alloy Straight Tee, Inconel Alloy 625 Reducing Coupling, Inconel 625 Hex Plug, Forged Straight Tees, Socket Weld Pipe Cap, Forged Pipe Cap, Equal Crossess, Inconel Alloy 625 Threaded Bushing, Inconel 625 Screwed Caps, Swedge Nipples |

| MSS-SP-79 | standard Practice covers ratings, tolerances, finish, dimensions, marking and material requirements for socket-welding | 625 Inconel Alloy Barrel Nipples, Inconel Alloy 625 Forged Threaded Boss, Alloy 625 Forged Hex Head Bull Plugs |

| MSS-SP-83 | Forged and Fabricated Socket-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Inconel Alloy 625 High Quality Socket weld 90° Elbow, Straight and Reducing-on-the-Tees, Alloy Forged 45° Short Radius Elbow, 625 Inconel caps, 3000LB Socket Weld Cross |

| MSS-SP-95 | Integrally Reinforced Forged Fittings – Socket Welding, Threaded, and Buttwelding Ends | Inconel 625 Socket weld Long Radius 90 Degree Elbows, Reducing Nipple, Socketweld Bushing, Threaded Plug, End Pipe caps, 625 Inconel Alloy Coupling |

Inconel 625 Socketweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM B564 625 Inconel Alloy Forged Fittings

Standard : ASTM B564 / ASME SB564

Dimensions : ASME/ANSI 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size : 1/8" NB to 4" NB

Type : Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure : Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.