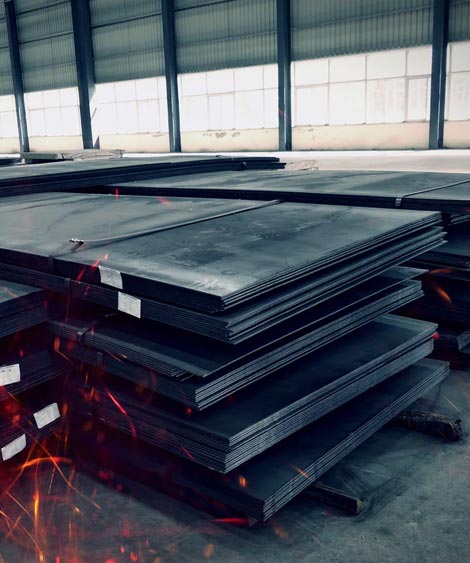

Astec Tubes has carved a niche as a manufacturer, distributor and exporter of BS EN 10130 DC01-07 carbon steel sheets and coils. Quality and excellence are core values that we uphold to guarantee that our products are excellent in the market.

The BS EN 10130 DC01-07 sheets and coils are the best product for use in the highest performance applications that involve the use of cold rolled steel. Satisfying the requirements of the EN 10130 standard, this steel sheets and coils is suitable for deep drawn parts due to the high degree of drawability and the smooth surface. It has uniform thickness and improved tensile strength, which makes it applicable in many industries.

BS EN 10130 DC01 to DC07 Carbon Steel Plate Specifications

DC01 Steel Equivalent Material

Material 1.0330, DC01 steel equivalent to ASTM, ISO, European (German DIN, British BSI, France NF), Japanese JIS and Chinese GB standard (for reference).

Note: DIN 1623 has been replaced by DIN EN 10130, and the designation ST12 has been replaced by DC01.

EN 10152

Chemical Composition

C01 steel chemical composition is listed in the following table based on ladle analysis.

Notes.

DC01+ZE Steel Mechanical Properties

The table below lists DC01+ZE steel mechanical properties.

Notes.

BS En 10130 DC01 - 07 Carbon Steel Plate Applications