Brass Forged Fittings provide outstanding ductility, formability, potency, and weldability. You can make these Brass Forged remarkably more robust and corrosion-resistant using aluminium. Brass Alloy fittings combined with manganese, iron, silicon, and aluminium can make them wear and tear-resistant. Aluminium also causes the formation of the aluminium oxide layer, which is thin, transparent and self-healing. These are made using ASTM, ASME/ANSI dimensions using different specifications like ASTM B687/ASME SB687. Brass Forged Fittings have many different types based on their applications. We are the best Brass Fittings Manufacturer.

Brass Forged Fittings Manufacturer

ANSI B16.11 Brass Threaded Forged Fittings, Brass Threaded Fittings, Brass Socketweld Fittings, Brass Forged Fittings, Brass Screwed Fittings Suppliers in Mumbai, India.

Table Of Content

Despite the increasing use of composite fittings, Brass Forged Fittings still represent a good option for many applications. These components are durable, resistant to vibration and mechanical shock, and have a high impact strength. Stainless Steel Forged Fittings are ideal for applications with essential long-term durability and excellent corrosion resistance.

These fittings are available in a wide range of sizes and designs. They can be customised, so creating a piece exactly the way you want is possible. They can be used for a variety of pressure settings, and they are also fire-resistant. They can handle temperatures that are much higher than other materials. They have excellent conductivity and are suitable for heating and cooling applications.

ANSI B16.11 Brass Threaded Forged Fittings, Brass Socketweld 90 Deg. Elbow, Brass Full Coupling, Brass Swedge Nipple, Brass Forged Equal Tee, Brass Forged Cross, Brass Socket-Weld End Cap, Brass Forged 90 Deg Elbow, Brass Threaded Plug, Brass Threaded Forged Fittings, Brass Socketweld Bushing, Brass Industrial Forged Fittings Manufacturer in India.

They are easy to cast, which means they can be made in different shapes. They are also an excellent choice for projects that require heavy-duty use. They have exceptional corrosion resistance and can be nickel-plated to accommodate fuel systems. They have a beautiful surface and can be moulded into a shape that suits your needs. They can be used in several environments, including hot water distribution systems.

Making a forged brass fitting begins with cutting a brass bar to the desired length. It is then heated and pressed under high pressure to form a smooth, dense material. Once it is cooled, it is trimmed off any flash. The material is then re-orientated in conformance with the contour part. It is then machined to finish it. The final product is typically a round part with rounded edges and a smooth surface.

The material is usually tempered, which increases its malleability. It has a low melting point and can handle a variety of cold and hot temperatures. It is a good choice for a hot water supply line and can tolerate higher temperatures than other materials. It can be annealed to produce a bright finish. They are also able to be fabricated, welded, and seamless. This is a very efficient way to make a pipe fitting, and it is recommended for industrial, commercial, and residential applications.

Brass Forged Elbow

Brass Forged Tee

Brass Forged Cross

Brass Forged Coupling

Brass Forged Plug

Brass Forged Union

Brass Forged Pipe Nipple

Brass Forged Bushing

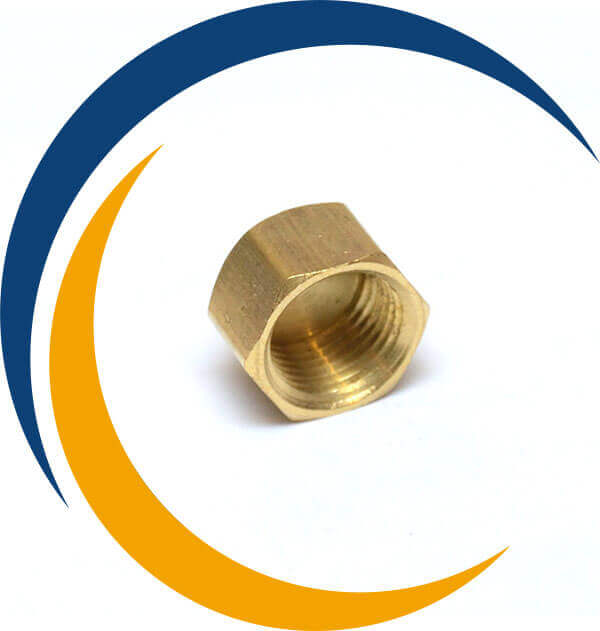

Brass Forged End Cap

Pressure Ratings of Brass Socketweld Fittings

| Products | Size | |

|---|---|---|

| ASTM B62 Brass Socket Weld / Threaded Elbows – Long Radius | ASTM B62 Brass Socket Weld / Threaded Stub Ends | Sizes 1/8″– 4″ Pressure Ratings – 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| ASTM B62 Brass Socket Weld / Threaded Elbows – Short Radius | ASTM B62 Brass Socket Weld / Threaded Crosses | |

| ASTM B62 Brass Socket Weld / Threaded Reducing Elbows | ASTM B62 Brass Socket Weld / Threaded Reducing Crosses | |

| ASTM B62 Brass Socket Weld / Threaded 45° Elbows | ASTM B62 Brass Socket Weld / Threaded 180° LR Return Bends | |

| ASTM B62 Brass Socket Weld / Threaded Tees | ASTM B62 Brass Socket Weld / Threaded 180° SR Return Bends | |

| ASTM B62 Brass Socket Weld / Threaded Tees | ASTM B62 Brass Socket Weld / Threaded Pipe Bends / Piggable Bends | |

| ASTM B62 Brass Socket Weld / Threaded Reducers | ASTM B62 Brass Socket Weld / Threaded Couplings | |

| ASTM B62 Brass Socket Weld / Threaded Concentric Reducers | ASTM B62 Brass Socket Weld / Threaded Pipe Nipples | |

| ASTM B62 Brass Socket Weld / Threaded Eccentric Reducers | ASTM B62 Brass Socket Weld / Threaded 90° LR / SR Elbow | |

| ASTM B62 Brass Socket Weld / Threaded 3D Elbow | ASTM B62 Brass Socket Weld / Threaded End Caps | |

| ASTM B62 Brass Socket Weld / Threaded 5D Elbow | ASTM B62 Brass Socket Weld / Threaded 45° LR / SR Elbow | |

Types of Brass Socketweld/Screwed/Threaded Fittings

Brass Socketweld 45 Deg Elbow

Brass Screwed Equal Elbow

Brass Equal Forged Tee

Brass Threaded Cross

ANSI B16.11 Brass Socket-Weld Elbow

Brass Pipe Nipples Exporter

Brass Forged Fittings Dealer

Brass Forged Fittings

Brass Reducing Coupling

Brass Half Coupling

Brass Forged Pipe Cap Supplier

Brass Socketweld End Cap

Brass Threaded Fittings

Brass Square Plug

Brass Socketweld Plug

Brass Threaded Fittings

Brass Forged Threaded Fittings

Brass Socket Weld Cap Manufacturer

Brass Pipe Union

Brass 90 deg. Elbow Stockist

Brass Forged Fittings Stockholder

Brass Socket Weld Fittings

Brass Reducing Cross Fittings

ANSI Brass Forged Fittings

Manufacturing Standards of Brass Forged Fittings Manufacturers in India & Globally

| ASME B16.11 | Factory-Made Wrought Socketweld Fittings | Brass Forged Screwed Elbows, Street Elbow, Brass Screwed Unequal Tee, Steel Straight Tee, Brass Reducing Coupling, Brass Hex Plug, Forged Straight Tees, Socket Weld Pipe Cap, Forged Pipe Cap, Equal Crossess, Brass Threaded Bushing, Brass Screwed Caps, Swedge Nipples |

| MSS-SP-79 | standard Practice covers ratings, tolerances, finish, dimensions, marking and material requirements for socket-welding | Brass Barrel Nipples, Brass Forged Threaded Boss, Brass Forged Hex Head Bull Plugs |

| MSS-SP-83 | Forged and Fabricated Socket-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Brass High Quality Socket weld 90° Elbow, Straight and Reducing-on-the-Tees, Forged 45° Short Radius Elbow, Brass caps, 3000LB Socket Weld Cross |

| MSS-SP-95 | Integrally Reinforced Forged Fittings – Socket Welding, Threaded, and Buttwelding Ends | Brass Socket weld Long Radius 90 Degree Elbows, Reducing Nipple, Socketweld Bushing, Threaded Plug, End Pipe caps, Brass Coupling |

Brass Socketweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

Brass Forged Fittings

Dimensions : ASME/ANSI 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size : 1/8" NB to 4" NB

Type : Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure : Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.