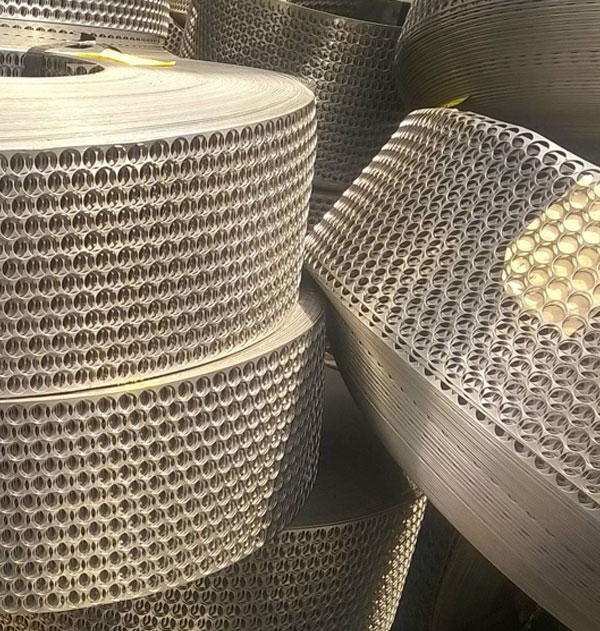

Stainless Steel FSS Scissel Coils combine good corrosion and heat resistance with good mechanical properties and resistance to organic acids and nitric acid. Ferritic Stainless Steel Scissels Coils exhibit higher resistance to stress corrosion cracking, making them a good choice for use in environments and applications where chlorides may be present, good ductility and formability, low thermal expansion, high thermal conductivity, and high oxidation resistance at high temperatures. FSS Scissel Coils have widespread use in furnaces, boiler heat exchangers, and other heat transfer applications. Generally used in applications where there is a need for good general corrosion resistance, like Stainless Steel Instrumentation Valves and FSS Scissel Coils, it can find it in water heaters, heat exchangers, and other internal applications. They are also used in decorative applications. They are beneficial in environments with high temperatures. They have high thermal conductivity and are highly resistant to stress corrosion cracking.

FSS Scissel Coils Supplier

Stainless Steel FSS Scissel Coils, SS FSS Scissel Coils Manufacturer, Jindal FSS Scissel Coils, MS FSS Scissel Coils, FSS Scissel Coils Exporter, FSS Scissel Coils Supplier, FSS Scissel Coils Suppliers in Mumbai, India.

These coils are manufactured from hot rolled steel sheeting that is usually unwound and passed through rolls to flex the plating. After the plating is annealed, the steel is washed to remove any acid that may have been deposited during the rolling process. The finished product is then coated with an outer metal cover to prevent rust from forming. The finished product is then wrapped in moisture-resistant paper packaging. It is often secured with flat metal strapping bands. These bands are applied transversely around the unit and are fixed on the outside circumference of the coil. There are typically three or four bands for each unit.FSS Scissel Coils are usually employed for nonstructural applications requiring good general or stress corrosion resistance, such as seawater applications. They can benefit internal and decorative applications where aesthetics are the primary consideration. FSS Scissel Coils are used in highly demanding environments, such as water tanks, exhaust systems, outdoor applications, heat exchangers, water heaters, and boilers.

Ferritic Stainless Steel FSS Scissel Coils, 400 Series FSS Scissel Coils, FSS Scissel Coils Dealer in Mumbai, Industrial FSS Scissel Coils, Mild Steel FSS Scissel Coils Manufacturer, FSS Scissel Coils Manufacturer in India.

The application of angle iron around the edges strengthens the outer packing. This provides more protection against handling damage. The inner packing is wrapped in moisture-resistant kraft paper to prevent moisture from entering the coil. The coil's diameter ranges from 1.000 to 1.400 mm, weighing 5 to 15 tons. Free moisture can seep into the coil between turns during the wrapping and packaging process. This can cause damage to the coil. It can lead to rusting, eroded surfaces, and pitting. The surface of the coil is oiled for added protection against rust. The width of the finished coil can be from 900 to 1.300 mm. The thickness of the coil can vary from one mm to five mm. A thin film of surface rust usually is not a problem. The surface of the coil is a mirror-like finish. The oblong package is then wrapped in a moisture-resistant metal envelope.

The package is then supported by wooden bearers, which impart strength and rigidity. The bearers are used to handle the coil by forklift trucks.The mechanical damage that can occur during handling is referred to as ovalisation. This happens when the side of the coil strikes an object. The coil can also be damaged by seawater. In such cases, the coil will not fit into decoiling machines. To avoid this, the coil should be lowered at low speeds. If the coil is reduced at high speed, the unit can be forced out of the round, resulting in severe handling problems. The FSS Scissel Coils are made from Ferritic Stainless Steel.

What are FSS Scissel Coils?

FSS Scissel Coils are a type of electromagnetic coil used in electromagnetic compatibility (EMC) testing & measurement. Stainless Steel FSS Scissel Coils are also known as resonant transformers.

What are FSS Scissel Coils used for?

Flexible Steel Strip Scissel Coils are used in a variety of industrial and commercial applications, including electrical power connections for moving equipment & as heating elements for a wide range of heating applications. They are also used as torsion springs in a variety of mechanical applications for which continuous flexing is required.

What are the benefits of using FSS Scissel Coils?

SS FSS Scissel Coils are highly efficient & can generate high voltage & high current pulses. FSS Scissel Coils are highly effective at shielding against electromagnetic interference (EMI), which makes them useful in electronic equipment, automobiles, & other applications where EMI can cause problems.

FSS Scissel Coils

Stainless Steel FSS Scissel Coils

MS FSS Scissel Coils

Types of FSS Scissel Coils

Stainless Steel FSS Scissel Coils

SS FSS Scissel Coils

SS 430 FSS Scissel Coils

Mild Steel FSS Scissel Coils

MS FSS Scissel Coils

400 Series FSS Scissel Coils

SS FSS Scissel Coils Dealers in Mumbai

Jindal FSS Scissel Coils

SS FSS Scissel Coils Stockholder

FSS Scissel Coils Supplier in Mumbai

FSS Scissel Coils Exporter

SS FSS Scissel Coils Stockist

MS FSS Scissel Coils Supplier in India

Ferritic Stainless Steel FSS Scissel Coils

FSS Scissel Coils Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

THICKNESS : 1.31 MM

WIDTH : 281MM , 373MM & 393 MM

HARDNESS : 140 +/-5(HV 30)

MATERIAL : Stainless Steel, Mild Steel

GRADE : SS 430 ( ALL 400 SERIES )