Astec Tubes not only manufactures but also supplies the Hastelloy C22 Forged Fittings. And these forged fittings are supplied to the clients across the world. We ensure that the clients get their desired fittings in dimensions. Our forged fittings are dimensionally accurate and manufactured using standard guidelines.

Hastelloy C22 Forged Fittings Manufacturer

Hastelloy 2.4602 Forged Fittings, Hastelloy® C22 Socketweld Fittings, Alloy C22 Forged Fittings, Hastelloy N06022 Forged Fittings, Hastelloy Alloy C22 Threaded Fittings, Hastelloy C22 Forged Fittings, ASTM B564 C22 Hastelloy Forged Fittings, Hastelloy C22 Screwed Fittings Suppliers in Mumbai, India.

Table Of Content

What is Hastelloy C22 Forged Fittings

Specification of ASTM B564 C22 Hastelloy Forged Fittings

ANSI B16.11 Available Types of Hastelloy C22 Forged Fittings

Hastelloy C22 Threaded Fittings Equivalent Grades

ASTM B564 Hastelloy C22 Threaded Fittings Chemical Composition

Hastelloy C22 Socketweld Fittings Mechanical Properties

Types of Hastelloy Alloy C22 Socketweld Fittings

The forged fittings are used in various industries for different applications. These are useful in a piping system that uses pipes below 2 or 4 inches. There are socket weld and threaded fittings under the forged fitting category. They are produced under different specifications over. These fittings are produced in various shapes such as elbow, caps, tees, couplings, adapters and more. Also, they are available in different sizes such as bore sizes of 4 inches or 1/8 diameter. In addition to this, the forged fittings are produced at different pressure ratings. The elbow 45/90 degrees change the pipe direction at different angles. Among them, a special fitting called street elbow is used.

However, these can be either straight or reducing. The Hastelloy C22 Forged Fittings like lateral have a Y shape that branch the pipe on the angle of 30 degrees. The forged plug is produced in different shapes like hex, squared, and round which blind the pipes. Bushings and couplings are two more types of fittings that you get at Astec tubes. Couplings are available in two sizes- half or full. We also produce reducers and reducer inserts that connect the pipes and decrease the size of the bore. The male and female unions are also produced that have rock wood design. The fittings are connected in different types of end such as socket or threaded.

C22 Hastelloy Socketweld 90 Deg. Elbow, Hastelloy C22 Swedge Nipple, ANSI B16.11 Hastelloy C22 Threaded Forged Fittings, C22 Hastelloy Forged Equal Tee, Hastelloy Alloy C22 Threaded Plug, Hastelloy C22 Forged 90 Deg Elbow, Nickel C22 Threaded Forged Fittings, ASME SB 564 Hastelloy C22 Socket-Weld End Cap, C22 Hastelloy Forged Cross, Alloy C22 Full Coupling, Hastelloy 2.4602 Socketweld Bushing, Hastelloy Alloy C22 Industrial Forged Fittings Manufacturer in India.

The socket weld offers fillet weld connection whereas threaded one offers connection using a screw. The former one is used in an application that requires long-lasting and strength. They are reliable fittings but take more time for installations. Threaded fittings are good for water distribution, cooling, fire protection and other installation where vibration and elongation don’t occur. All the forged fittings undergo test without it we don’t supply the products to the clients. Hardness test, flaring, micro test, ultrasonic test, and more are conducted on the fittings.

Hastelloy C22 Forged Elbow

Hastelloy C22 Forged Tee

Hastelloy C22 Forged Cross

Hastelloy C22 Forged Coupling

Hastelloy C22 Forged Plug

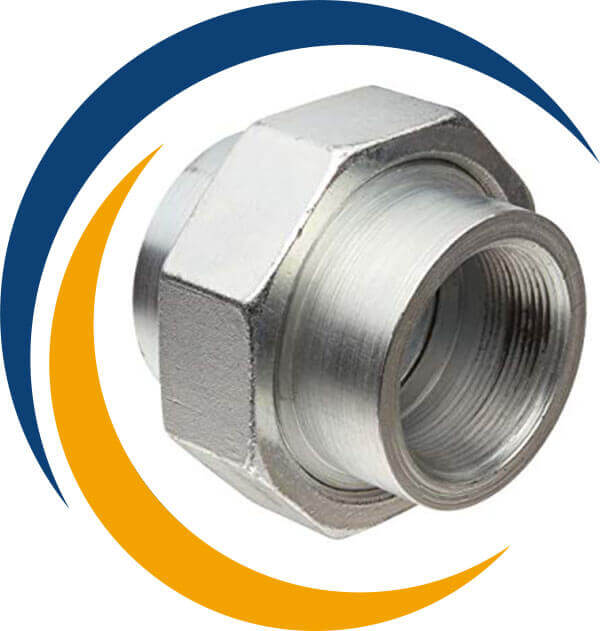

Hastelloy C22 Forged Union

Hastelloy C22 Forged Pipe Nipple

Hastelloy C22 Forged Bushing

Hastelloy C22 Forged End Cap

Hastelloy C22 Threaded Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN | OR |

| Hastelloy C22 | 2.4602 | N06022 | NW 6022 | - | NiCr21Mo14W | - |

ASTM B564 Hastelloy C22 Threaded Forged Fittings Chemical Composition

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

ANSI B16.11 Hastelloy C22 Socketweld Fittings Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000, MPa – 690 | Psi – 45000, MPa – 310 | 45 % |

Types of Hastelloy C22 Socketweld/Screwed/Threaded Fittings

UNS N06022 Socketweld 45 Deg Elbow

Hastelloy C22 Screwed Equal Elbow

Hastelloy C22 Equal Forged Tee

Hastelloy Alloy 2.4602 Threaded Cross

ANSI B16.11 Hastelloy C22 Socket-Weld Elbow

Hastelloy C22 Pipe Nipples Exporter

Hastelloy 2.4602 Forged Fittings Dealer

Alloy C22 Forged Fittings

UNS N06022 Reducing Coupling

Hastelloy 2.4602 Half Coupling

Hastelloy C22 Forged Pipe Cap Supplier

Hastelloy C22 Socketweld End Cap

UNS N06022 Threaded Fittings

Hastelloy Alloy C22 Square Plug

ASME SB 564 Hastelloy C22 Socketweld Plug

Alloy 2.4602 Threaded Fittings

UNS N06022 Forged Threaded Fittings

Hastelloy C22 Socket Weld Cap Manufacturer

Hastelloy Alloy C22 Pipe Union

Hastelloy C22 90 deg. Elbow Stockist

Hastelloy C22 Forged Fittings Stockholder

ASTM B564 Hastelloy C22 Socket Weld Fittings

Hastelloy C22 Reducing Cross Fittings

ANSI B16.11 Hastelloy C22 Forged Fittings

Manufacturing Standards of Hastelloy C22 Forged Fittings Manufacturers in India & Globally

| ASME B16.11 | Factory-Made Wrought Socketweld Fittings | C22 Hastelloy Forged Screwed Elbows, Street Elbow, C22 Hastelloy Screwed Unequal Tee, C22 Steel Straight Tee, Hastelloy C22 Reducing Coupling, Hastelloy C22 Hex Plug, Forged Straight Tees, Socket Weld Pipe Cap, Forged Pipe Cap, Equal Crossess, Hastelloy C22 Threaded Bushing, Hastelloy C22 Screwed Caps, Swedge Nipples |

| MSS-SP-79 | standard Practice covers ratings, tolerances, finish, dimensions, marking and material requirements for socket-welding | C22 Hastelloy Barrel Nipples, Hastelloy C22 Forged Threaded Boss, Hastelloy C22 Forged Hex Head Bull Plugs |

| MSS-SP-83 | Forged and Fabricated Socket-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Hastelloy C22 High Quality Socket weld 90° Elbow, Straight and Reducing-on-the-Tees, Forged 45° Short Radius Elbow, C22 Hastelloy caps, 3000LB Socket Weld Cross |

| MSS-SP-95 | Integrally Reinforced Forged Fittings – Socket Welding, Threaded, and Buttwelding Ends | Hastelloy C22 Socket weld Long Radius 90 Degree Elbows, Reducing Nipple, Socketweld Bushing, Threaded Plug, End Pipe caps, C22 Hastelloy Coupling |

Hastelloy Alloy C22 Socketweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM B564 C22 Hastelloy Alloy Forged Fittings

Standard : ASTM B564 / ASME SB564

Dimensions : ASME/ANSI 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size : 1/8" NB to 4" NB

Type : Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure : Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.