Astec Tubes is a prominent industry that at a global level is dealing with many clients as a manufacturer, supplier, and exporter. To fulfill the demands of our esteem patrons we are making these forged fittings available at various specifications, standards, dimensions, types, sizes, schedules, pressure ratings, etc. It is also designed and supplied to the clients at custom-made specifications to meet any special application desires. Our manufactured ranges of Super Duplex Steel S32760 Forged Fittings are designed by using premium quality of alloy and according to the set manufacturing norms. Also, these forged fittings are confirming product quality standards like ASME, ASTM, and API, etc.

Super Duplex Steel S32760 Forged Fittings Manufacturer

Super Duplex Steel S32760 Threaded Fittings, Super Duplex S32760 Socketweld Fittings, Super Duplex Steel UNS S32760 Forged Fittings, ASTM A815 Super Duplex Steel S32760 Forged Fittings, Super Duplex 32760 Forged Fittings, Super Duplex 1.4410 Forged Fittings, Super Duplex S32760 Screwed Fittings Suppliers in Mumbai, India.

Table Of Content

What is Super Duplex Steel S32760 Forged Fittings

Specification of ASTM A815 S32760 Super Duplex Steel Forged Fittings

ANSI B16.11 Available Types of Super Duplex 2507 Forged Fittings

Super Duplex S32760 Threaded Fittings Equivalent Grades

ASTM A815 Super Duplex 32760 Threaded Fittings Chemical Composition

Super Duplex S32760 Socketweld Fittings Mechanical Properties

Types of Super Duplex Steel S32760 Socketweld Fittings

The types of forged fittings that we provide to our clients are forged boss, forged equal cross, Socketweld unequal tee, street elbows, threaded bushing, square head plug, end cap, hex plug, screwed barrel nipple, forged 90 deg elbow, threaded reducing tee, forged pipe cap, threaded union, Socketweld 45 deg elbow, full coupling, and pipe nipple. The product is widely appreciated as it is having many good properties and it today has become an ideal selection for various applications in different industries. The properties are good dimensional accuracy, smooth surface finishes, long serviceability, pitting resistance, crevice corrosion resistance, stress corrosion cracking resistance, non-corrosive body, heat treatable, holds high temperature & pressure, good weldability, good machinability, etc.

The applications where we see these forged fittings found used are pulp and paper industry, offshore oil drilling industry, power generation, condensers, heat exchangers, petrochemicals, seawater equipment, gas processing, chemical equipment, specialty chemicals, pharmaceuticals equipment, pharmaceuticals, etc. Super Duplex S32760 is the very high resistance to corrosion grade of super duplex SS material. This material is quite 10% lighter than the other alloy and is having a very good performance at the cryogenic temperatures. This steel grade is having very good weldability and machinability.

S32760 Super Duplex Steel Forged Cross, ASME SA 815 Super Duplex S32760 Socket-Weld End Cap, S32760 Super Duplex Socketweld 90 Deg. Elbow, Super Duplex Steel S32760 Threaded Forged Fittings, Super Duplex 32760 Threaded Plug, ANSI B16.11 Super Duplex S32760 Threaded Forged Fittings, S32760 Super Duplex Steel Forged Equal Tee, Super Duplex 32760 Forged 90 Deg Elbow, Super Duplex Steel S32760 Full Coupling, Super Duplex S32760 Swedge Nipple, Super Duplex 1.4410 Socketweld Bushing, Super Duplex Steel S32760 Industrial Forged Fittings Manufacturer in India.

Super Duplex S32760 Forged Fittings before delivered to the clients is sent for thorough product quality tests. The tests done on these forged fittings are PMI & IGC tests, toughness tests, hydrostatic tests, radiography tests, chemical tests, mechanical tests, etc. The packaging of these fittings is done carefully to ensure its safety against damages when shipped.

Super Duplex S32760 Forged Elbow

Super Duplex Steel S32760 Forged Tee

Super Duplex Steel S32760 Forged Cross

Super Duplex S32760 Forged Coupling

Super Duplex Steel S32760 Forged Plug

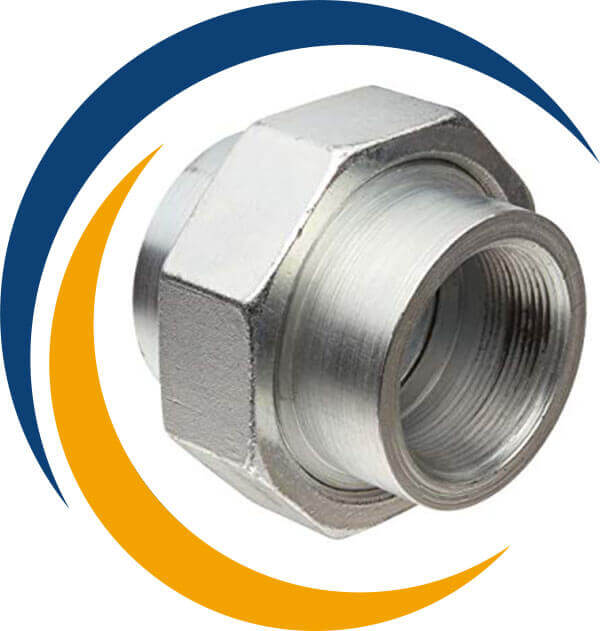

Super Duplex Steel S32760 Forged Union

Super Duplex Steel S32760 Forged Pipe Nipple

Super Duplex Steel S32760 Forged Bushing

Super Duplex Steel S32760 Forged End Cap

Super Duplex Steel S32760 Threaded Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex Steel | 1.4410 | S32760 |

ASTM A815 Super Duplex Steel S32760 Threaded Forged Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

ANSI B16.11 Super Duplex Steel S32760 Socketweld Fittings Mechanical Properties

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32760 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

Types of Super Duplex S32760 Socketweld/Screwed/Threaded Fittings

UNS S32760 Socketweld 45 Deg Elbow

Super Duplex S32760 Screwed Equal Elbow

Super Duplex S32760 Equal Forged Tee

Super Duplex Steel 1.4410 Threaded Cross

ANSI B16.11 Super Duplex S32760 Socket-Weld Elbow

Super Duplex S32760 Pipe Nipples Exporter

Super Duplex 1.4410 Forged Fittings Dealer

Super Duplex S32760 Forged Fittings

UNS S32760 Reducing Coupling

Super Duplex 1.4410 Half Coupling

Super Duplex S32760 Forged Pipe Cap Supplier

Super Duplex S32760 Socketweld End Cap

UNS S32760 Threaded Fittings

Super Duplex Steel S32760 Square Plug

ASME SA 815 Super Duplex S32760 Socketweld Plug

1.4410 Threaded Fittings

UNS S32760 Forged Threaded Fittings

Super Duplex 32760 Socket Weld Cap Manufacturer

Super Duplex Steel S32760 Pipe Union

Super Duplex S32760 90 deg. Elbow Stockist

Super Duplex S32760 Forged Fittings Stockholder

ASTM A815 Super Duplex S32760 Socket Weld Fittings

Super Duplex S32760 Reducing Cross Fittings

ANSI S32760 Super Duplex Forged Fittings

Manufacturing Standards of Super Duplex S32760 Forged Fittings Manufacturers in India & Globally

| ASME B16.11 | Factory-Made Wrought Socketweld Fittings | S32760 Super Duplex Steel Forged Screwed Elbows, Street Elbow, S32760 Super Duplex Steel Screwed Unequal Tee, S32760 Steel Straight Tee, Super Duplex S32760 Reducing Coupling, Super Duplex S32760 Hex Plug, Forged Straight Tees, Socket Weld Pipe Cap, Forged Pipe Cap, Equal Crossess, Super Duplex S32760 Threaded Bushing, Super Duplex Steel S32760 Screwed Caps, Swedge Nipples |

| MSS-SP-79 | standard Practice covers ratings, tolerances, finish, dimensions, marking and material requirements for socket-welding | S32760 Super Duplex Steel Barrel Nipples, Super Duplex Steel S32760 Forged Threaded Boss, Super Duplex S32760 Forged Hex Head Bull Plugs |

| MSS-SP-83 | Forged and Fabricated Socket-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Super Duplex Steel S32760 High Quality Socket weld 90° Elbow, Straight and Reducing-on-the-Tees, Forged 45° Short Radius Elbow, S32760 Super Duplex Steel caps, 3000LB Socket Weld Cross |

| MSS-SP-95 | Integrally Reinforced Forged Fittings – Socket Welding, Threaded, and Buttwelding Ends | Super Duplex Steel S32760 Socket weld Long Radius 90 Degree Elbows, Reducing Nipple, Socketweld Bushing, Threaded Plug, End Pipe caps, S32760 Super Duplex Coupling |

Super Duplex Steel S32760 Socketweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM A815 S32760 Super Duplex Steel Forged Fittings

Standard : ASTM A815 / ASME SA815

Dimensions : ASME/ANSI 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size : 1/8" NB to 4" NB

Type : Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure : Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.