Astec Tubes manufactures and supply pipe fittings of various types using a high-quality grade alloy, WPHY 60. However, we manufacture Carbon Steel WPHY 60 Pipe Fittings in different specifications and dimensions. Also, we produce these products as per the dimensions required by our clients. The fittings are a simple component used in many industries for providing a safe and leakage-free connection. Fittings are also used for terminating or extending the length of the pipe by connecting two pipes. Some fittings also connect four pipes. Fittings are the general product of the piping system. However other industries like chemical, petrochemical, hydraulic plants, power plants, marine industries, seawater, wastewater equipment, municipal, and others also use them. Every industry has different requirement therefore the same fitting is not useful. Other fittings type elbow, union, cross, tee, couplings, reducer, adapter, connector, outlet, plug, cap, stub end, and more are used in different industries according to the requirements.

Carbon Steel WPHY 60 Pipe Fittings Manufacturer

ASTM A860 WPHY 60 Carbon Steel Pipe Fittings, WPHY 60 Pipe Fittings, Carbon Steel WPHY 60 Butt weld Reducer, High Yield CS WPHY 60 Pipe Fitting, Carbon Steel WPHY 60 Buttweld Fittings, Carbon Steel WPHY 60 Buttweld Fittings Suppliers in Mumbai, India.

Table Of Content

What is Carbon Steel WPHY 60 Pipe Fittings

Specification of ASTM A860 WPHY 60 Pipe Fittings

Available Types of Carbon Steel WPHY 60 Pipe Fittings

ASTM A860 WPHY 60 Pipe Fittings Chemical Composition

ANSI B16.9 CS WPHY 60 Pipe Fittigns Mechanical Properties

Types of Carbon Steel WPHY 60 Buttweld Fittings

Each fitting is having property to survive under the conditions experienced in these industries. The atmosphere inside the industry has a chemical, high temperature, and even high pressure. Fittings should be strong and durable to provide their function. The use of WPHY 60 alloy ensures that they can work under those conditions. The alloy offers fatigue strength, temperature strength, corrosion resistance, and more properties. Among all corrosion resistance is the most desired property of the industries. Therefore, the High Yield WPHY 60 Butt weld Fittings have high resistance to corrosion including general and local corrosion. As a result, they can resist against attack causing crevice corrosion, pitting, and stress corrosion cracking. These are caused by chemicals such as acetic acid, organic acid, chlorine, nitric acid, and more acids. Henceforth, our fittings are good for use in high-pressure oil and gas transportation systems. They offer to seal tight connections without causing any leakage.

High Yield WPHY 60 Eccentric Reducer, Carbon Steel WPHY 60 Buttweld 90 Deg. Elbow, ANSI B16.9 Carbon Steel WPHY 60 Welded Pipe Fittings, ASME SA860 CS WPHY 60 Pipe Cap, High Yield WPHY 60 Concentric Reducer, High Yield WPHY 60 Pipe Bend, High Yield CS WPHY 60 Seamless Butt weld Fittings, Carbon Steel WPHY 60 Stub End, High Yield CS WPHY 60 Equal Tee, High Yield CS WPHY 60 Pipe Elbow, Carbon Steel WPHY 60 Industrial Pipe Fittings Manufacturer in India.

However, to check the performance of fittings testing is necessary. They are also conducted as per the guidelines. We perform tests such as chemical analysis, hardness test, mechanical test, pitting test, impact resistance test, flaring test, flattening test, and more. Besides this, fittings are packed in durable materials for careful transportation. High-quality packaging materials are used at Astec Tubes.

Carbon Steel WPHY 60 Butt weld Elbow

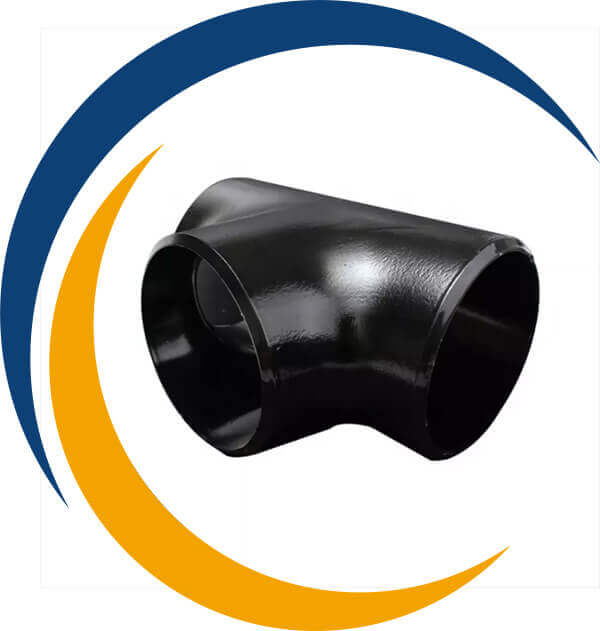

Carbon Steel WPHY 60 Butt weld Tee

Carbon Steel WPHY 60 Butt weld Cross

Carbon Steel WPHY 60 Butt weld Reducer

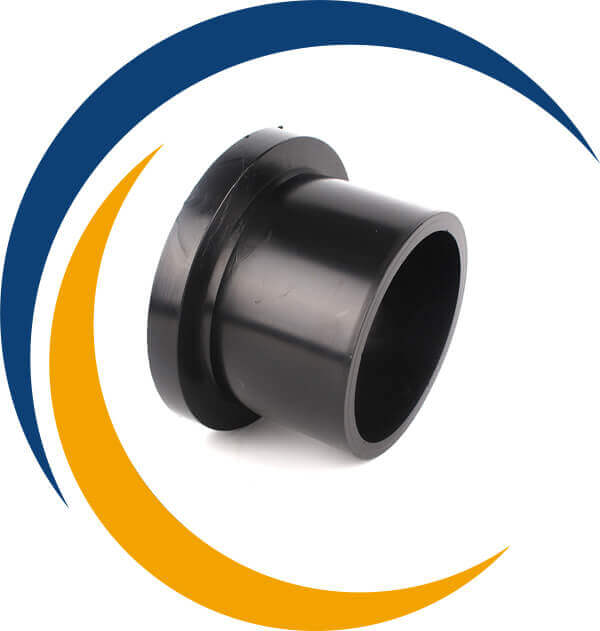

Carbon Steel WPHY 60 Butt weld Stub End

Carbon Steel WPHY 60 Butt weld Pipe Bend

ASTM A860 High Yield Carbon Steel WPHY 60 Butt weld Pipe Fittings Chemical Composition

| Grade | C | Mn | S | P | Si | Ni | Cr | Mo | Cu | Ti | V | Cb | Al |

| WPHY 60 | 0.20 | 1.00-1.45 | 0.03 | 0.01 | 0.15-0.40 | 0.50 | 0.30 | 0.25 | 0.35 | 0.05 | 0.10 | 0.06 |

ANSI B16.9 Carbon Steel WPHY 60 Buttweld Fittigns Mechanical Properties

| Element | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| WPHY 60 | 515-690 | 415 | 28 % |

Types of Carbon Steel WPHY 60 Buttweld Fittings

High Yield WPHY 60 Buttweld Elbow

Carbon Steel WPHY 60 Pipe Elbow

Carbon Steel WPHY 60 Equal Tee

High Yield CS WPHY 60 Butt weld Cross

ANSI B16.9 CS WPHY 60 Welded Elbow

Carbon Steel WPHY 60 Reducer Exporter

High Yield WPHY 60 Pipe Fittings

High Yield WPHY 60 Eccentric Reducer

High Yield WPHY 60 Concentric Reducer

Carbon Steel WPHY 60 Pipe Cap Supplier

High Yield WPHY 60 Buttweld End Cap

High Yield WPHY 60 Butt weld Fittings

Carbon Steel WPHY 60 Long Stub End

ASME SA860 CS WPHY 60 Bend

High Yield WPHY 60 Pipe Fittings

WPHY 60 Short Stub End Manufacturer

Carbon Steel WPHY 60 Pipe Bend

CS WPHY 60 90 deg. Elbow Stockist

CS WPHY 60 Pipe Fittings Stockholder

ASTM A860 CS WPHY 60 Welded Fittings

High Yield WPHY 60 Seamless Fittings

Manufacturing Standards of Carbon Steel WPHY 60 Pipe Fittings Manufacturers in India & Globally

| ASME B16.9 | Factory-Made Wrought Buttwelding Fittings | WPHY 60 Long Radius Elbows, Long Radius Reducing Elbows, High Yield WPHY 60 Long Radius Returns, High Yield CS WPHY 60 Steel Short Radius Elbows, Carbon Steel WPHY 60 Short Radius 180-deg Rerurns, Carbon Steel WPHY 60 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Carbon Steel WPHY 60 Lap Joint Stub Ends, Carbon Steel WPHY 60 Caps, Reducers |

| ASME B16.28 | High Yield WPHY 60 Short Radius Elbows, Carbon Steel WPHY 60 Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | High Yield Carbon Steel WPHY 60 Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, WPHY 60 Carbon Steel WPHY 60 caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | High Yield Carbon Steel WPHY 60 Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, WPHY 60 reducers |

High Yield Carbon Steel WPHY 60 Buttweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM A860 Carbon Steel WPHY 60 Pipe Fittings

Standard : ASTM A860 / ASME SA860

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1/8” NB TO 48” NB.

Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

Type : Seamless / Welded / Fabricated

Bending Radius :R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom