Astec Tubes is the globally recommended manufacturer, supplier, and exporter of the very good quality of wider ranges of Alloy Steel F91 flanges. Our AS F91 collar flanges are having very good quality, high tensile strength, and rugged construction, excellent resistance to general corrosion, flawless finishes, resistance to chloride SCC and sulfuric acid. Type F91 lap joint flanges are having a chromium content of about 20-14% and it can be thus used at the temperature to 1725-1850 deg F. AS plate flanges are having temperature ranges wherein resistance to the general corrosion is quite essential. Slip-on flanges are showing very good resistance to the atmospheric condition and few chemicals and water. Flat face flanges are widely used in the AS flanges family.

Alloy Steel F91 Flanges Manufacturer

ASTM A182 Alloy Steel F91 Weld Neck Flanges, Chrome Moly 1.4903 Socket weld Flanges, ANSI B16.5 Alloy Steel F91 Flanges, Alloy Steel K90901 Flanges, Alloy Steel F91 Slip on Flanges, Alloy Steel F91 Flanges, Alloy Steel F91 Flanges Suppliers in Mumbai, India.

Table Of Content

What is Alloy Steel F91 Flanges

Specification of ASTM A182 Alloy Steel F91 Pipe Flanges

Available Types of Alloy Steel F91 Flanges

Alloy Steel F91 Flanges Equivalent Grades

ASTM A182 Alloy Steel F91 Pipe Flanges Chemical Composition

ANSI B16.5 Alloy Steel F91 Flanges Mechanical Properties

Types of Alloy Steel F91 Flanges

We as a customer-focused dealer to meet all our esteem patrons’ demands are providing these Alloy Steel F91 flanges at different sizes, standards, dimensions, specifications, classes, face types. It is too manufactured and offered to our clients based upon the application requirements or as per the product specifications our clients give to us. The benefit of our complete ranges of flanges is the long service life, clean finishes, low maintenance, etc.

Alloy Steel F91 Industrial Flanges, Cr-Mo F91 Lap Joint Flanges, Alloy Steel F91 Pipe Flanges, Alloy Steel K90901 RTJ Flanges, CrMo F91 Blind Flanges, Chromium Molybdenum Steel F91 Flanges, Alloy Steel F91 Spectacle Blind Flanges, ASME SA 182 Chrome Moly F91 Plate Flanges, Alloy Steel 1.4903 Flange, Alloy Steel F91 Flanges Manufacturer in India.

AS F91 threaded flanges and AS F91 spectacle blind flanges are supplied normally in tempered, normalized or tempered & quenched conditions. AS F91 welding neck flanges are giving very good services wherein resistance to general corrosion is quite essential.

The industry standards that our offered ranges of Alloy Steel F91 flanges are confirming are ANSI, ASME, EN, BS, and DIN, etc. It can be collected from us at different classes like 2500#, 1500#, 900#, 600#, 400#, 300# and 150#. Certain applications where these flanges are used to a greater extent are petrochemicals, pharmaceuticals, oil & gas industry, food processing, seawater equipment, chemical industry, specialty chemicals, pharmaceutical industry, heat exchangers, condensers, power generations, pulp & paper industry.

The testing is done on all our produced ranges of Alloy Steel F91 flanges for checking how good the strength is. The tests are intergranular corrosion tests, hardness tests, PMI testing, pitting resistance tests, etc. The TC provided are EN 10204/3.1b, third party test report, radiography test report, and raw material certificates, etc.

Alloy Steel F91 Slip on Flanges

Alloy Steel F91 Weld Neck Flanges

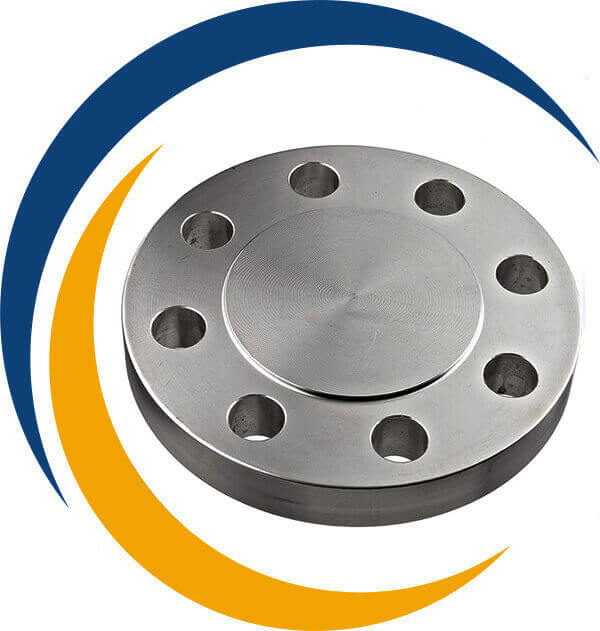

Alloy Steel F91 Blind Flanges

Alloy Steel F91 Threaded Flanges

Alloy Steel F91 Socket weld Flanges

Alloy Steel F91 Lap Joint Flanges

Alloy Steel F91 RTJ Flanges

Alloy Steel F91 Long Weld Neck Flanges

Alloy Steel F91 Spectacle Blind Flange

Alloy Steel F91 Flanges Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | Trade Name |

| Alloy Steel F91 | K90901 | 1.4903 | 9Cr-1Mo-V |

ASTM A182 Alloy Steel F91 Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F91 | 0.08 - 0.12 | 0.3 - 0.6 | 0.5 | 0.01 | 0.02 | 8.5 - 9.5 | 0.85 - 1.05 |

ANSI B16.5 Alloy Steel F91 Flanges Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| Alloy Steel F91 | 415 | 585 | 20 |

Types of Alloy Steel F91 Flanges

UNS K90901 Flanges

Alloy Steel F91 Slip on Flanges

Chrome Moly F91 SORF Flanges

UNS K90901 Threaded Flanges

CrMo 1.4903 Flanges

Chrome Moly Steel F91 Pipe Flange Exporter

ANSI B16.36 CrMo F91 Orifice Flanges

Alloy Steel F91 Weld Neck Flanges

Chrome Moly F91 WNRF Flanges

UNS K90901 SWRF Flange Supplier

Chromium Molybdenum 1.4903 Forged Flange

Alloy Steel F91 Long Weld Neck Flanges

ANSI B16.5 Alloy Steel F91 Plate Flange

Alloy Steel Gr. F91 Lap Joint Flanges

Alloy Steel F91 Blind Flanges

Alloy Steel F91 RTJ Flanges Manufacturer

Chrome Moly F91 BLRF Flanges

UNS K90901 Plate Flanges Stockist

CrMo F91 Reducing Flanges Stockholder

Alloy Gr.F91 Ring Type Joint Flanges

ANSI B16.5 Alloy Steel F91 Square Flange

Manufacturing Standards of Alloy Steel F91 Flanges Manufacturers in India & Globally

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Alloy Steel F91 Flanges Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM A182 Alloy Steel F91 Flanges

Specifications : ASTM A182 / ASME SA182

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2" (15 NB) to 48" (1200NB)

Class/Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Type : Slip on flanges, Socket weld flanges, Forged flanges, Blind flanges, Welding neck flange, Ring type joint flange, Spectacle blind flange, Reducing flange, Threaded / Screwed flange, Tongue and Groove flange, Long weld neck flange, Flat flange, Industrial flanges, Plate flange, ASME B16.5 flanges.