We Astec Tubes is a reliable manufacturer, supplier, exporter and stockiest of the wider ranges of industrial products. Today we are specializing in manufacturing and providing extensive ranges of Alloy Steel F12 Flanges to the global and local clients. Our clients can access these flanges in wider ranges of specifications, dimensions, and sizes. These flanges of alloy steel are discovering applications in different sectors. These flanges are crafted mainly for the long term purposes. Flanges are the important part of any type of construction work and can be easily made in used for the construction of malls and buildings etc. These flanges are designed according to the request made by the clients as well. These F12 flanges are designed by using very good quality of raw substances and by using the latest equipment and machinery. All our ranges are confirming industry standards like ASTM, ASME, and API, etc.

Alloy Steel F12 Flanges Manufacturer

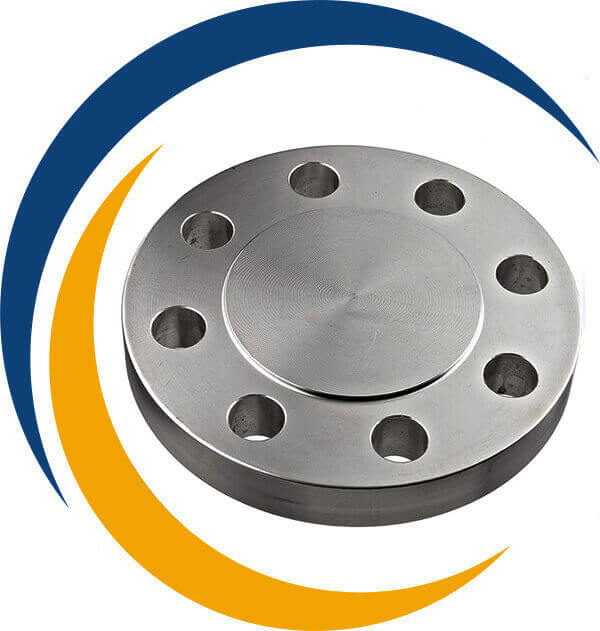

Alloy Steel F12 Slip on Flanges, Chrome Moly K11564 Socket weld Flanges, Alloy Steel F12 Flanges, ANSI B16.5 Alloy Steel F12 Flanges, Alloy Steel K11562 Flanges, ASTM A182 Alloy Steel F12 Weld Neck Flanges Alloy Steel F12 Flanges Suppliers in Mumbai, India.

Table Of Content

What is Alloy Steel F12 Flanges

Specification of ASTM A182 Alloy Steel F12 Pipe Flanges

Available Types of Alloy Steel F12 Flanges

Alloy Steel F12 Flanges Equivalent Grades

ASTM A182 Alloy Steel F12 Pipe Flanges Chemical Composition

ANSI B16.5 Alloy Steel F12 Flanges Mechanical Properties

Types of Alloy Steel F12 Flanges

Alloy Steel F12 Flanges are quite convenient to install and they also demand less maintenance. These F12 flanges are an ideal solution for greater temperature and greater pressure atmospheres. They are well known for their superior quality and long-lastingness. These flanges are having other attributes like the anti-corrosive body, resistance to general corrosion, pitting, crevice corrosion, and stress corrosion cracking, etc.

Alloy Steel K11562 RTJ Flanges, CrMo F12 Blind Flanges, Cr-Mo F12 Flanges, Alloy Steel F12 Lap Joint Flanges, Alloy Steel F12 Pipe Flanges, Alloy Steel F12 Spectacle Blind Flanges, Chromium Molybdenum F12 Industrial Flanges, ASME SA 182 Chrome Moly Steel F12 Plate Flanges, Alloy Steel K11564 Flange, Chrome Moly F12 Flanges Manufacturer in India.

There are many applications where we can see these flanges used extensively. Those applications are like condensers, seawater equipment, pharmaceutical equipment, specialty chemicals, petrochemicals, offshore oil drilling industry, pulp & paper industry, heat exchangers, chemical equipment, pharmaceuticals, gas processing, power generation, etc.

The several types of Alloy Steel F12 Flanges are available that clients can avail to meet their application demands. Those types are socket weld flanges, threaded flanges, slip-on flanges, weld neck flanges, plate flanges, lap joint flanges, reducing flanges, blind flanges, forged flanges, orifice flanges, square flanges, and ring type joint flanges.

Alloy Steel F12 Flanges are quality checked and then supplied to the clients. The tests that are performed on it for quality assurance are PMI tests, chemical composition checking, pitting corrosion tests, radiography tests, hydrostatic tests, etc. The packaging of these flanges is done by individually wrapping using plastic sheets and then placed into carton/wooden boxes.

Alloy Steel F12 Slip on Flanges

Alloy Steel F12 Weld Neck Flanges

Alloy Steel F12 Blind Flanges

Alloy Steel F12 Threaded Flanges

Alloy Steel F12 Socket weld Flanges

Alloy Steel F12 Lap Joint Flanges

Alloy Steel F12 RTJ Flanges

Alloy Steel F12 Long Weld Neck Flanges

Alloy Steel F12 Spectacle Blind Flange

Alloy Steel F12 Flanges Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy Steel F12 | K11562/K11564 | - |

ASTM A182 Alloy Steel F12 Flanges Chemical Composition

| Grade | C | Mn | P | S | Si | Ni | Ch | Mo |

| F12 | 0.15 max | 0.30-0.60 | 0.030 max | 0.030 max | 0.50-1.00 | - | 1.00-1.50 | 0.44-0.65 |

ANSI B16.5 Alloy Steel F12 Flanges Mechanical Properties

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation |

| 415 | 205 | 20 % |

Types of Alloy Steel F12 Flanges

UNS K11562 Flanges

Alloy Steel F12 Slip on Flanges

Chromium Molybdenum F12 SORF Flanges

UNS K11562 Threaded Flanges

CrMo K11564 Flanges

Chrome Moly F12 Pipe Flange Exporter

ANSI B16.36 Cr-Mo F12 Orifice Flanges

Alloy Steel F12 Weld Neck Flanges

Chrome Moly F12 WNRF Flanges

UNS K11562 SWRF Flange Supplier

CrMo K11564 Forged Flange

Alloy Steel F12 Long Weld Neck Flanges

ANSI B16.5 Alloy Steel F12 Plate Flange

Alloy Steel Gr. F12 Lap Joint Flanges

ANSI B16.5 Alloy Steel F12 Square Flange

Alloy Steel F12 Blind Flanges

Alloy Steel F12 RTJ Flanges Manufacturer

Chrome Moly F12 BLRF Flanges

UNS K11562 Plate Flanges Stockist

CrMo F12 Reducing Flanges Stockholder

Chromium Molybdenum Steel Gr.F12 Ring Type Joint Flanges

Manufacturing Standards of Alloy Steel F12 Flanges Manufacturers in India & Globally

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Alloy Steel F12 Flanges Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM A182 Alloy Steel F12 Flanges

Specifications : ASTM A182 / ASME SA182

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2" (15 NB) to 48" (1200NB)

Class/Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Type : Slip on flanges, Socket weld flanges, Forged flanges, Blind flanges, Welding neck flange, Ring type joint flange, Spectacle blind flange, Reducing flange, Threaded / Screwed flange, Tongue and Groove flange, Long weld neck flange, Flat flange, Industrial flanges, Plate flange, ASME B16.5 flanges.