Astec Tubes is a leading manufacturer, dealer, and stockiest of the industrial products with excellent quality in the product. We maintain the stock of the entire industrial products. We even manufacture the customized form of the product as per the customer instruction and dimensions. F46 Forged Fittings is designed with various chemical compositions such as manganese, phosphorous, carbon, sulfur, silicon, nickel, titanium, vanadium, aluminum, cobalt, molybdenum, chromium, and copper. We manufacture the forged fitting with both physical and mechanical properties such as tensile strength, yield strength, ultimate tensile strength, elongation, melting point, thermal conductivity, electrical conductivity, and so on as well.

Carbon Steel F46 Forged Fittings Manufacturer

Carbon Steel F46 Forged Fittings, Carbon Steel F46 Socketweld Fittings, Carbon Steel F46 Threaded Fittings, ANSI B16.11 Carbon Steel F46 Threaded Forged Fittings, WPHY F46 Carbon Steel Screwed Fittings Suppliers in Mumbai, India.

Table Of Content

What is CS F46 Forged Fittings

Specification of ASTM A694 Carbon Steel Forged Fittings

ANSI B16.11 Available Types of F46 CS Forged Fittings

ASTM A694 CS Threaded Fittings Chemical Composition

WPHY F46 Carbon Steel Socketweld Fittings Mechanical Properties

Types of Carbon Steel F46 Socketweld Fittings

These fitting are also constructed with the help of many specifications such as dimensions, size, shape, applications, bending radius, thickness, grade, type, surface, forms, tolerance and so on as well. These forged fittings are available in many types and forms such as seamless, fabricated, and welded. F46 Forged Fittings are applicable in many industries such as pharmaceutical industries, petrochemical industry, offshore oil drilling industries, power generation industries, specialty chemicals industry, paper industry, pulp industry, gas processing industry, food processing industries, and so on. These fittings are also useful for many general purposes such as chemical equipment, heat exchangers, pharmaceutical equipment, condensers, chemical equipment, and seawater equipment.

F46 Forged Fittings are made with excellent mechanical and physical properties. These fitting have the feature of striking and resisting the rust of the industrial waste. These are suitable for use in the high chemical industries with resistance to the entire general corrosions. The forged fitting is made with the best quality of the raw material with the resistance from the deformations of the climatic changes. These fitting are offering the assistance of the durability of the product with the high strength of the entire products. These forged fitting are resistant from the corrosions like crevice corrosion, seawater rust, pitting corrosion and so on as well.

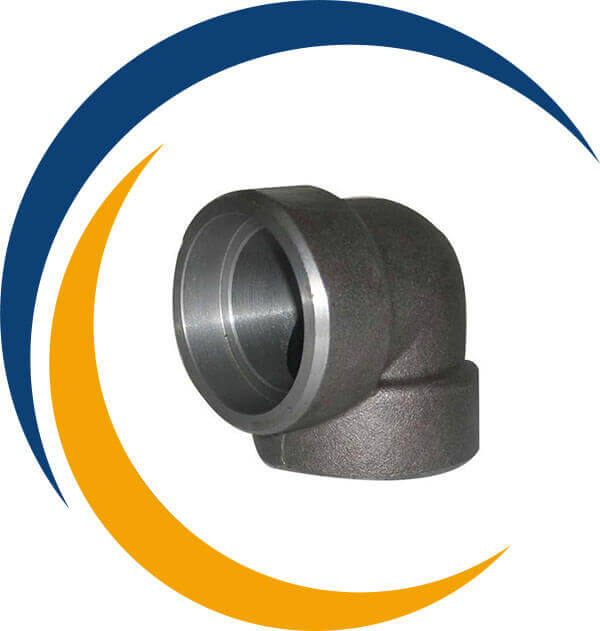

CS F46 Forged 90 Deg Elbow, CS F46 Threaded Plug, Carbon Steel F46 Full Coupling, WPHY F46 Carbon Steel Forged Cross, Carbon Steel F46 Swedge Nipple, WPHY F46 Carbon Steel Forged Equal Tee, Carbon Steel F46 Socketweld Bushing, ANSI B16.11 Carbon Steel F46 Threaded Forged Fittings, Carbon Steel F46 Socketweld 90 Deg. Elbow, Carbon Steel F46 Threaded Forged Fittings, ASME SA 694 Carbon Steel Socket-Weld End Cap, Carbon Steel F46 Industrial Forged Fittings Manufacturer in India.

F46 Forged Fittings have to undergo many tests after the production form the industries such as pitting resistance test, macro test, micro test, flaring test, flattening test, mechanical test, chemical test, PMI test, hardness test, radiography test, intergranular test, and spectro analysis test so on as well.

Carbon Steel Forged Elbow

Carbon Steel Forged Tee

Carbon Steel Forged Cross

Carbon Steel Forged Coupling

Carbon Steel Forged Plug

Carbon Steel Forged Union

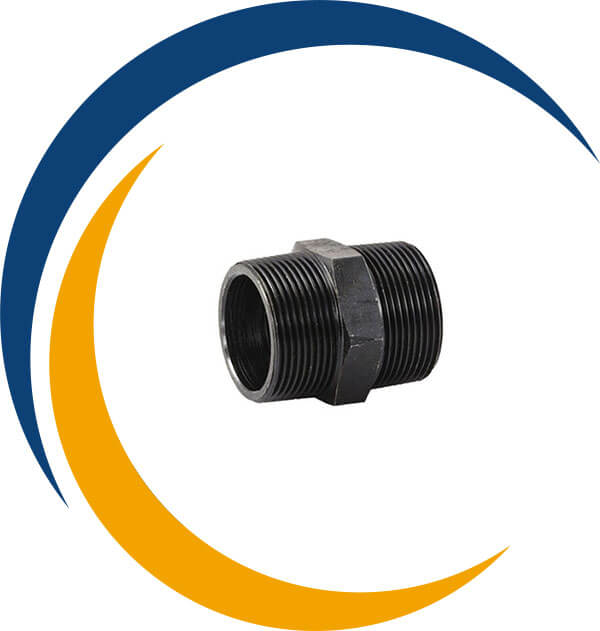

Carbon Steel Forged Pipe Nipple

Carbon Steel Forged Bushing

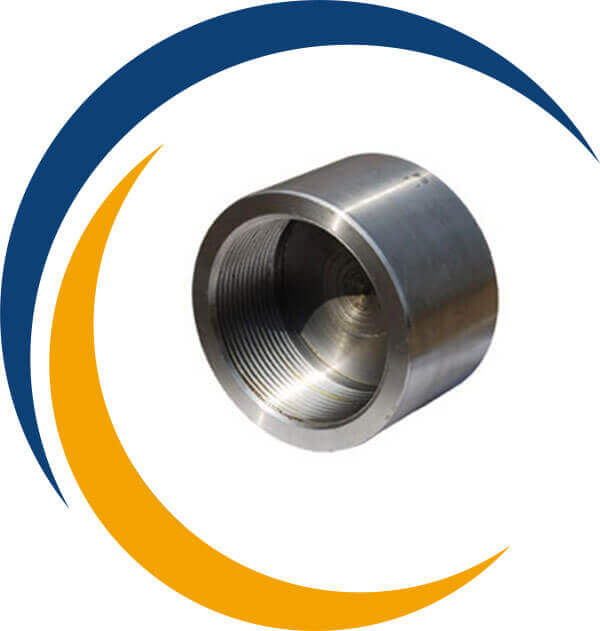

Carbon Steel Forged End Cap

ASTM A694 Carbon Steel F46 Threaded Forged Fittings Chemical Composition

| Grade | C | Si | Mn | P | S | Mo | Ni | Cr | Cu | V | Nb |

| F46 | 0.13-0.20 | 0.20-0.40 | 1.20-1.60 | ≤ 0.030 | ≤ 0.020 | - | ≤ 0.30 | ≤ 0.30 | ≤ 0.25 | - | - |

ANSI B16.11 Carbon Steel F46 Socketweld Fittings Mechanical Properties

| Grade | Yield Strength, Min (KSI ) | Tensile Strength, Min (KSI) |

| A694 | 46 | 60 |

Types of WPHY F46 Carbon Steel Socketweld/Screwed/Threaded Fittings

CS F46 Socketweld 45 Deg Elbow

Carbon Steel F46 Screwed Equal Elbow

Carbon Steel F46 Equal Forged Tee

CS F46 Threaded Cross

ANSI B16.11 Carbon Steel F46 Socket-Weld Elbow

WPHY F46 Carbon Steel Pipe Nipples Exporter

Carbon Steel F46 Forged Fittings Dealer

CS F46 Forged Fittings

High Yield CS F46 Reducing Coupling

Carbon Steel F46 Half Coupling

Carbon Steel F46 Forged Pipe Cap Supplier

Carbon Steel F46 Socketweld End Cap

CS F46 Threaded Fittings

Carbon Steel F46 Square Plug

ASME SA 694 Socketweld Plug

Carbon Steel F46 Threaded Fittings

CS F46 Forged Threaded Fittings

WPHY F46 Carbon Steel Socket Weld Cap Manufacturer

High Yield CS F46 Pipe Union

Carbon Steel F46 90 deg. Elbow Stockist

Carbon Steel F46 Forged Fittings Stockholder

ASTM A694 Socket Weld Fittings

CS F46 Reducing Cross Fittings

ANSI 16.11 Carbon Steel F46 Forged Fittings

Manufacturing Standards of Carbon Steel F46 Forged Fittings Manufacturers in India & Globally

| ASME B16.11 | Factory-Made Wrought Socketweld Fittings | CS F46 Forged Screwed Elbows, Street Elbow, Carbon Steel F46 Screwed Unequal Tee, Steel Straight Tee, Carbon Steel F46 Reducing Coupling, Carbon Steel F46 Hex Plug, Forged Straight Tees, Socket Weld Pipe Cap, Forged Pipe Cap, Equal Crossess, CS F46 Threaded Bushing, Carbon Steel F46 Screwed Caps, Swedge Nipples |

| MSS-SP-79 | standard Practice covers ratings, tolerances, finish, dimensions, marking and material requirements for socket-welding | Carbon Steel F46 Barrel Nipples, CS F46 Forged Threaded Boss, Carbon Steel F46 Forged Hex Head Bull Plugs |

| MSS-SP-83 | Forged and Fabricated Socket-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Carbon Steel F46 High Quality Socket weld 90° Elbow, Straight and Reducing-on-the-Tees, Forged 45° Short Radius Elbow, CS F46 caps, 3000LB Socket Weld Cross |

| MSS-SP-95 | Integrally Reinforced Forged Fittings – Socket Welding, Threaded, and Buttwelding Ends | CS F46 Socket weld Long Radius 90 Degree Elbows, Reducing Nipple, Socketweld Bushing, Threaded Plug, End Pipe caps, Carbon Steel F46 Coupling |

Carbon Steel F46 Socketweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM A694 CS Forged Fittings

Standard : ASTM A694 / ASME SA 694

Dimensions : ASME/ANSI 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size : 1/8" NB to 4" NB

Type : Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure : Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.