Astec tubes are a trustworthy manufacturer and supplier of stainless steel, carbon steels, Hastelloy steels, etc. We maintain the superior quality of Alloy Steel WP91 Pipe Fittings. This particular grade is well known for its great performance in high pressures. They are widely used in making the attachments between the pipes or valve for ensuring no leakage in all critical conditions. It has splendid welding and cold working properties. The specifications and dimensions of this alloy steel are manufactured in adherence with ASTM / ASME A/SA 182, ANSI/ASME B16.11 and BS3799, etc. It provides elongation to 20%. The general chemical composition of this alloy is consisting 0.02% sulfur, 8.5 o 9.5 % chromium, 0.85-1.05% molybdenum, 0.08 to 0.12% of carbon, 0.3 to 0.6 manganese, 0.5% silicon, and 0.01% phosphorus. Grade F19 showcase great versatility, machinability, higher impact properties, long wear life span and grain-refining. Our Alloy Steel WP91 Pipe Fittings are widespread in the engineering and textile industries. It is also preferred in non-critical jobs like cooling systems and fire protection systems.

Alloy Steel WP91 Pipe Fittings Manufacturer

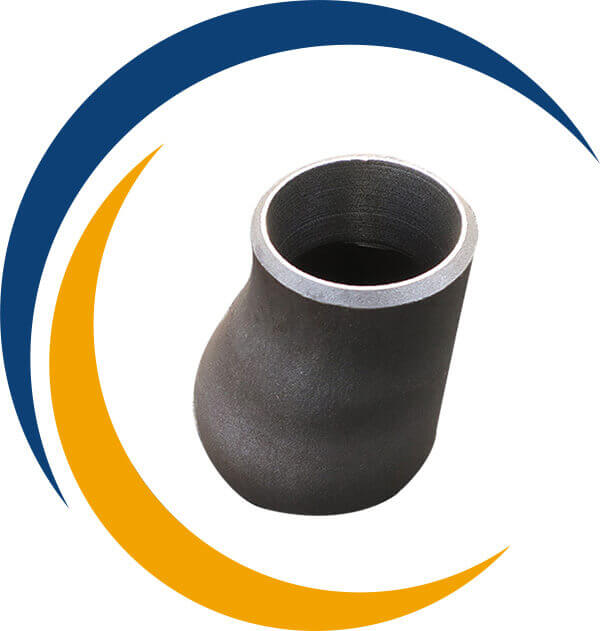

Alloy Steel WP91 Pipe Fitting, Chrome Moly WP91 Pipe Fitting, Alloy Steel WP91 Butt weld Reducer, ASTM A234 WP91 Alloy Steel Pipe Fittings, Alloy Steel WP91 Buttweld Fittings, Alloy Steel WP91 Buttweld Fittings Suppliers in Mumbai, India.

Table Of Content

What is Alloy Steel WP91 Pipe Fittings

Specification of ASTM A234 Alloy Steel WP91 Pipe Fittings

Available Types of Alloy Steel WP91 Pipe Fittings

ASTM A234 AS WP91 Butt weld Fittings Chemical Composition

ANSI B16.9 CrMo WP91 Pipe Fittigns Mechanical Properties

Types of Alloy Steel WP91 Buttweld Fittings

They are also widely used in the construction of the chemical plant, vessels, pipework and also applied to structural hollow sections and pressure purposes, etc. Other than this, the Pharmaceuticals, Chemical Equipment, Sea Water Equipment, Heat Exchangers, Condensers, and Pulp and Paper Industry make great use of it. In general, grade 791 can be in socket weld or threaded weld. Socketweld is mostly used for absorbing high pressures but for small or nominal pipes. Likewise, Threaded forging is the type of pipe fittings used for less costly and non-critical works. They are easily identifiable from their appearances. If you find threading on the inner lining surface of the fitting then it is threaded. Similarly, if the surface is all clean and polished then it Socketweld fitting.

Alloy Steel WP91 Buttweld 90 Deg. Elbow, Chrome Moly WP91 Seamless Butt weld Fittings, ASME SA234 CrMo WP91 Pipe Cap, Alloy Steel WP91 Eccentric Reducer, Alloy Steel WP91 Concentric Reducer, Alloy Steel WP91 Stub End, Alloy Steel WP91 Equal Tee, Chrome Moly WP91 Pipe Elbow, CRMO WP91 Pipe Bend, ANSI B16.9 Alloy Steel WP91 Welded Pipe Fittings, Alloy Steel WP91 Buttweld Fitting, Alloy Steel WP91 Industrial Pipe Fittings Manufacturer in India.

Alloy Steel WP91 Butt weld Fittings are packed as per specifications given by every customer and shipped with all the documents and sometimes a simple guide for applying the fittings. Also, the certifications should be inclusive of at least a Manufacturer Test Certificate according to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, and Third Party Inspection Report.

Alloy Steel WP91 Butt weld Elbow

Alloy Steel WP91 Butt weld Tee

Alloy Steel WP91 Butt weld Cross

Alloy Steel WP91 Butt weld Reducer

Alloy Steel WP91 Butt weld Stub End

Alloy Steel WP91 Butt weld Pipe Bend

ASTM A234 Alloy Steel WP91 Butt weld Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | S | P | Cr | Mo |

| A234 WP91 | 0.08-0.12 | 0.3-0.6 | 0.2-0.5 | ≤0.02 | ≤0.015 | 8-9.5 | 0.85-1.05 |

ANSI B16.9 Alloy Steel WP91 Buttweld Fittigns Mechanical Properties

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| A234 WP91 | ≥590 | ≥415 | ≥20 |

Types of Alloy Steel WP91 Buttweld Fittings

Alloy Steel WP91 Buttweld Elbow

Alloy Steel WP91 Pipe Elbow

Alloy Steel WP91 Equal Tee

Chrome Moly WP91 Butt weld Cross

ANSI B16.9 AS WP91 Welded Elbow

Alloy Steel WP91 Reducer Exporter

Chrome Moly WP91 Pipe Fittings

CrMo WP91 Pipe Fittings

Alloy Steel WP91 Eccentric Reducer

Chrome Moly WP91 Concentric Reducer

Alloy Steel WP91 Pipe Cap Supplier

CRMO WP91 Buttweld End Cap

Alloy Steel WP91 Butt weld Fittings

Alloy Steel WP91 Long Stub End

ASME SA234 AS WP91 Buttweld Bend

Alloy Steel WP91 Butt weld Fittings

Alloy Steel WP91 Pipe Fittings

AS WP91 Short Stub End Manufacturer

Alloy Steel WP91 Pipe Bend

Alloy Steel WP91 90 deg. Elbow Stockist

CrMO WP12 Pipe Fittings Stockholder

ASTM A234 AS WP91 Welded Fittings

Alloy Steel WP91 Seamless Fittings

Alloy Steel CrMo WP91 Pipe Fittings

Manufacturing Standards of Alloy Steel WP91 Pipe Fittings Manufacturers in India & Globally

| ASME B16.9 | Factory-Made Wrought Buttwelding Fittings | Alloy Stel WP91 Long Radius Elbows, Long Radius Reducing Elbows, AS WP91 Long Radius Returns, WP91 Steel Short Radius Elbows, Alloy Steel WP91 Short Radius 180-deg Rerurns, Alloy Steel WP91 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Alloy Steel WP91 Lap Joint Stub Ends, Alloy Steel WP91 Caps, Reducers |

| ASME B16.28 | Alloy Steel WP91 Short Radius Elbows, Alloy Steel WP91 Short Radius 180-deg Returns | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Alloy Steel WP91 Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, WP91 Alloy Steel WP91 caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

| Mss SP75 | Alloy Steel WP91 Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, WP91 Alloy reducers |

Alloy Steel WP91 Buttweld Fittings Applications

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Sea Water Equipment

- Power Generation

ASTM A234 Alloy Steel WP91 Pipe Fittings

Standard :ASTM A234 / ASME SA234

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

Type : Seamless / Welded / Fabricated

Bending Radius : R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom