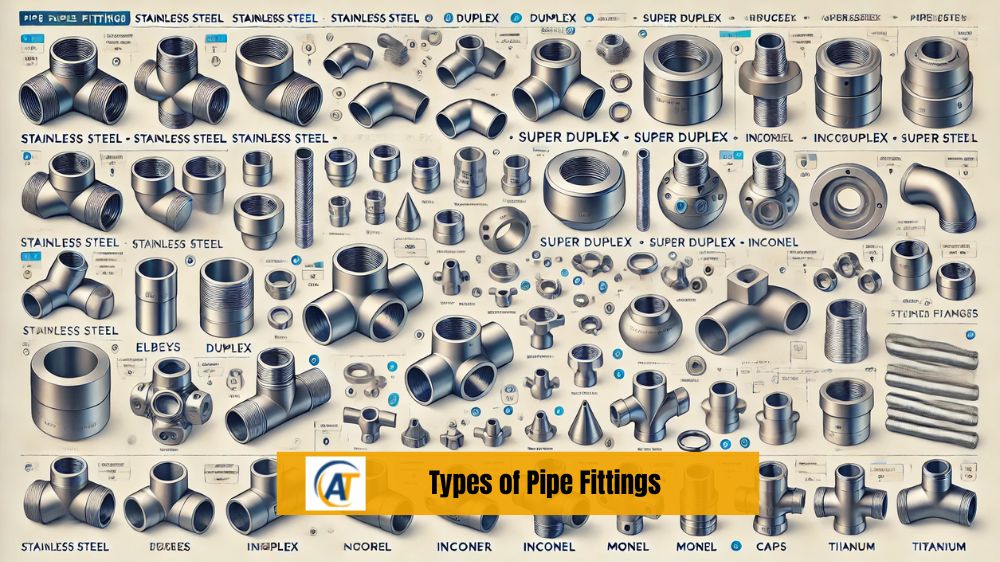

Pipe fittings are vital components in various industries, connecting, redirecting, and controlling the flow of fluids or gases through pipes. Whether for plumbing, industrial applications, or specialized systems, selecting the right type of pipe fitting is crucial for efficiency, safety, and longevity. This blog will delve into various types of pipe fittings made from materials such as Stainless Steel, Duplex, Super Duplex, Inconel/Incoloy, Monel, and Titanium—including their grades, benefits, and common applications.

What Are Pipe Fittings?

Pipe fittings are devices used to connect or modify the direction and flow of a pipe system. They come in a variety of forms, such as elbows, tees, reducers, couplings, unions, and flanges. The materials used for these fittings depend on the environment and conditions under which they will be used, such as pressure, temperature, and chemical exposure.

Common Types of Pipe Fittings and Their Materials

- Elbow Fittings

- Function: Elbows are used to change the direction of flow in pipes, typically at angles of 45° or 90°.

- Applications: Plumbing, HVAC systems, oil and gas pipelines, water treatment facilities.

- Materials & Grades:

- Stainless Steel 304/316: Ideal for general applications involving low to moderate temperatures.

- Duplex 2205: Perfect for applications involving higher pressures and aggressive environments.

- Super Duplex 2507: Best for highly corrosive environments, such as seawater and chemical plants.

- Inconel 625: High-temperature applications like aerospace and power plants.

- Titanium Grade 2: Used in marine, chemical processing, and aerospace due to its corrosion resistance.

- Tee Fittings

- Function: Tee fittings allow for a branch to be connected to a pipe, making them a key component in any system that requires fluid or gas to be diverted in multiple directions.

- Applications: Water distribution, wastewater systems, irrigation, chemical industries.

- Materials & Grades:

- Stainless Steel 304/316: Widely used in water, food, and pharmaceutical industries.

- Duplex 2205: Suitable for higher-strength needs, like offshore platforms.

- Incoloy 825: Ideal for chemical processing, especially where sulfuric acid is involved.

- Monel 400: Frequently used in marine environments due to its excellent resistance to seawater corrosion.

- Reducer Fittings

- Function: Reducers are used to change the size of a pipe, allowing for a smooth flow between different diameters.

- Applications: Systems requiring pressure reduction or where the flow volume changes, such as in fuel lines and hydraulic systems.

- Materials & Grades:

- Stainless Steel 304/316: General-purpose applications in plumbing, heating, and chemical industries.

- Duplex 2205: High-pressure systems such as oil rigs and chemical plants.

- Titanium Grade 5: High-temperature, high-performance systems where corrosion resistance is essential.

- Couplings

- Function: Couplings are used to connect two sections of a pipe, enabling a quick and reliable connection.

- Applications: HVAC, water systems, plumbing, oil and gas pipelines.

- Materials & Grades:

- Stainless Steel 304/316: Ideal for medium to high-temperature applications where corrosion resistance is needed.

- Monel 400: Used for highly corrosive environments, especially in marine applications.

- Inconel 600: High-temperature applications like power generation and aerospace.

- Union Fittings

- Function: Unions provide a method for connecting and disconnecting pipe sections without removing the entire assembly.

- Applications: Systems where pipes need to be frequently disconnected for maintenance or modifications.

- Materials & Grades:

- Stainless Steel 304/316: Used in sanitary, food, and pharmaceutical systems.

- Duplex 2205: For aggressive environments with high pressures.

- Inconel 625: Common in aerospace and chemical plants.

- Cap Fittings

- Function: Caps are used to close the end of a pipe, preventing the flow of fluid or gas through the pipe.

- Applications: Used in maintenance, system closures, and during installation.

- Materials & Grades:

- Stainless Steel 304/316: General-purpose piping systems.

- Super Duplex 2507: Highly resistant to corrosion in aggressive environments like seawater and offshore applications.

- Titanium Grade 2: Common in marine and high-pressure chemical applications.

- Nipple Fittings

- Function: Nipples are short lengths of pipe with male threads at both ends, used to connect other fittings.

- Applications: Frequently used in plumbing, heating systems, and gas lines.

- Materials & Grades:

- Stainless Steel 304/316: Common in water systems and food processing.

- Titanium Grade 5: Used in aerospace, medical, and high-performance applications due to its high strength and lightweight properties.

- Flange Fittings

- Function: Flanges are used to connect pipes or to connect a pipe to a valve, pump, or other equipment. Flanges provide a reliable seal to prevent leaks.

- Applications: Ideal for high-pressure systems, such as in refineries, power plants, and chemical processing.

- Materials & Grades:

- Stainless Steel 304/316: Most commonly used in general industrial applications.

- Duplex 2205: Used in highly corrosive environments like oil refineries.

- Super Duplex 2507: Known for superior strength and corrosion resistance in harsh environments.

- Inconel 625: Ideal for high-temperature and corrosive environments in power plants and chemical industries.

Types of Pipe Fittings by Material and Grade

1. Stainless Steel Pipe Fittings

- Benefits: Stainless steel is known for its excellent corrosion resistance, strength, and versatility. It is used in applications requiring high cleanliness, resistance to rust, and mechanical strength.

- Common Grades:

2. Duplex Stainless Steel Pipe Fittings

- Benefits: Duplex stainless steel is a hybrid of austenitic and ferritic structures, offering high strength, improved resistance to stress corrosion, and excellent weldability.

- Common Grade:

- Duplex 2205: Used for applications involving high pressure and aggressive environments like offshore platforms, desalination plants, and chemical processing.

3. Super Duplex Stainless Steel Pipe Fittings

- Benefits: Super Duplex steel has higher strength and corrosion resistance than Duplex grades. It is ideal for extremely harsh environments.

- Common Grade:

- Super Duplex 2750: Widely used in chemical processing, seawater desalination, and offshore oil and gas industries.

4. Inconel/Incoloy Pipe Fittings

- Benefits: Inconel and Incoloy alloys are high-performance materials known for their excellent resistance to heat, oxidation, and corrosion. They are often used in extreme temperature environments.

- Common Grades:

- Inconel 625: Used in aerospace, chemical processing, and power generation due to its high-temperature stability and resistance to oxidation.

- Incoloy 825: Ideal for handling corrosive chemicals, such as in sulfuric acid and phosphoric acid environments.

5. Monel Pipe Fittings

- Benefits: Monel alloys are highly resistant to corrosion, especially in marine environments. They are durable and can handle both acidic and alkaline conditions.

- Common Grade:

- Monel 400: Used in marine, chemical, and power generation industries, offering exceptional corrosion resistance.

6. Titanium Pipe Fittings

- Benefits: Titanium is known for its exceptional strength-to-weight ratio, making it ideal for high-performance applications where weight and corrosion resistance are critical.

- Common Grades:

- Titanium Grade 2: Suitable for general-purpose applications in marine, chemical, and HVAC systems.

- Titanium Grade 5 (Ti-6Al-4V): Offers high strength and corrosion resistance, commonly used in aerospace and medical implants.

Conclusion

Pipe fittings are integral to the functionality and durability of piping systems. Choosing the right material and grade for your application is essential to ensure long-term performance and resistance to corrosion, high temperatures, and pressure. By understanding the properties of Stainless Steel, Duplex, Super Duplex, Inconel/Incoloy, Monel, and Titanium pipe fittings, you can select the most appropriate components for your specific needs.

Always consult a professional when choosing pipe fittings, as the right material and grade can make a significant difference in the performance and longevity of your system.