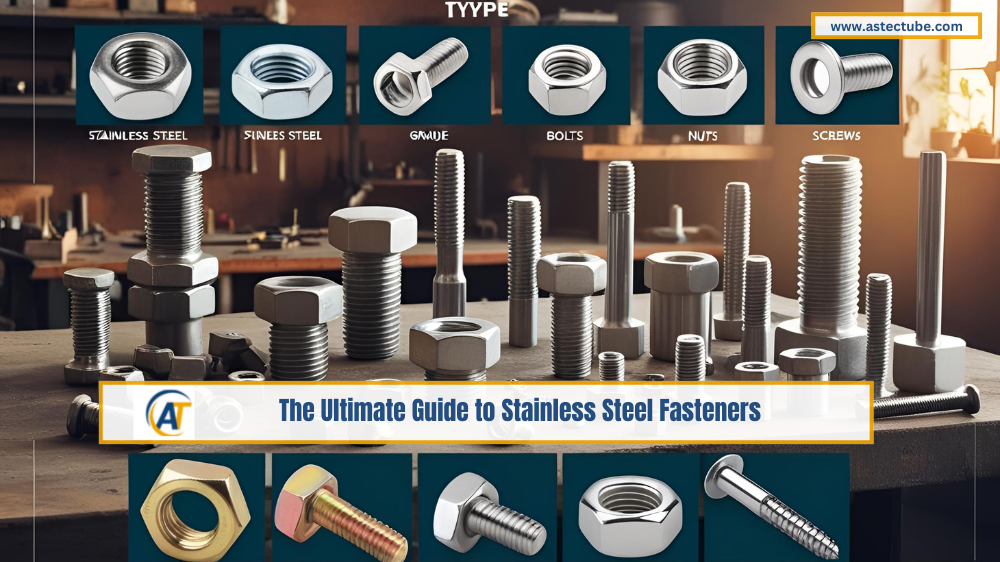

Stainless steel fasteners are essential mechanical parts that joins components together, including bolts, screws, nuts, washers, and rivets. These fasteners are vital in various industries like construction, automotive, marine, and aerospace because of their impressive durability and resistance to corrosion. In this blog, we’ll dive into the various types of stainless steel fasteners, explore their material grades, highlight key properties and guide you on how to choose the perfect fastener for your specific needs.

What Are Stainless Steel Fasteners?

Fasteners play a crucial role in mechanically joining materials, whether it’s a permanent or temporary connection. Stainless steel is usually the material of choice when it comes to fasteners due its superior rust resistance, long-life capability and ability to operate in harsh environments. Stainless steel fasteners provide superior reliability over many other materials whether in wet conditions or at elevated temperatures.

Types of Stainless Steel Fasteners

Bolts and Screws: Threaded fasteners are used in a wide range of assemblies. Bolts pair with nuts, while screws can often be used alone. Found in machinery, construction, and automotive applications.

Nuts: Internally threaded components used to secure bolts and screws. Common types include hex nuts, lock nuts, and wing nuts.

Washers: Washers are flat circular rings that are utilized underneath bolt heads or nuts. They distribute the load in an even way and act as protectors against surface damage. Also they play a role in keeping things tight by reducing the chances of loosening caused by vibrations.

Studs and threaded rods: Rod-shaped fasteners with external threading. Ideal for high-load structures, and machinery that requires strong tension joints.

Rivets: Non-threaded, permanent fasteners used in aircraft, automotive bodies and structural sheet metal work.

Specialty Fasteners (Anchors, Clips, Clamps): It is used for specific applications like securing wires, concrete mounting, and piping support in construction and electrical setups.

Stainless Steel Grades Used in Fasteners

Understanding grades helps ensure the right fastener for the application.

Grade 304: Versatile and widely used, this grade offers excellent corrosion resistance and is ideal for general construction, furniture and kitchen equipment.

316 grade: It includes molybdenum which provides elevated resistance to corrosion, especially when exposed to marine and chemical environments.

Grade 321: Titanium-stabilized, it resists heat and is used in aerospace and high-temperature applications.

Duplex and Super Duplex: These offer superior strength and resistance to stress corrosion. Common in offshore, petrochemical, and desalination plants.

Other Grades (410, 430): Grade 410 is hard and wear-resistant—used in tooling. Grade 430 offers good corrosion resistance and is used in automotive trim and appliances.

Key Properties of Stainless Steel Fasteners

- Corrosion Resistance: High chromium content forms a protective layer to resist rust.

- Strength and Durability: Suitable for high-stress and load-bearing applications.

- Temperature Tolerance: Performs in both high and low temperature settings.

- Aesthetic Appeal: Smooth finish makes them ideal for visible and decorative installations.

- Low Maintenance: Resistant to staining and oxidation with minimal upkeep.

How to Choose the Right Stainless Steel Fastener

Selecting the correct fastener depends on environmental conditions, mechanical load, and exposure to chemicals or moisture. Choose the appropriate grade and type based on your application’s demands. Always ensure the product complies with international standards such as ASTM, ISO, or DIN to ensure quality and performance.

Common Applications of Stainless Steel Fasteners

- Construction and Infrastructure: It is used in bridges, buildings, and highways for strength and weather resistance.

- Automotive and Aerospace: Essential in high-performance, vibration-resistant components.

- Marine and Offshore: Grade 316 fasteners are standard due to saltwater resistance.

- Food and Pharma: Hygienic and non-reactive, ideal for sanitary environments.

- Electronics and Electrical: It is used in enclosures and internal hardware.

- Renewable Energy: They are found in solar, wind, and hydro energy systems.

Advantages of Using Stainless Steel Fasteners

These fasteners offer a long service life, excellent rust resistance, and low maintenance. Their recyclability adds an eco-friendly advantage. Though initially costlier, they provide long-term savings due to reduced replacement and maintenance needs.

Challenges and Considerations

Stainless steel fasteners may have a higher upfront cost compared to carbon steel. Galling thread seizure during tightening is a concern, but can be managed using lubricants and proper installation. Ensure correct torque values and always follow best practices for safety and longevity.

Conclusion

Choosing the right stainless steel fastener ensures structural safety, performance, and longevity. With various types and grades available, aligning your choice with project-specific requirements is key. For critical applications, consult experts and rely on certified products to meet quality standards and ensure lasting performance.