Alloy 625 is a nickel-chromium-molybdenum alloy for its excellent strength, high-temperature properties, and corrosion resistance. Because of its properties and versatility, alloy 625 is used in various industries, such as chemical processing, marine engineering, and aerospace. In this blog post, we will provide a complete guide to alloy 625 fittings, including what they are, their features, and their applications.

What Are Alloy 625 Fittings?

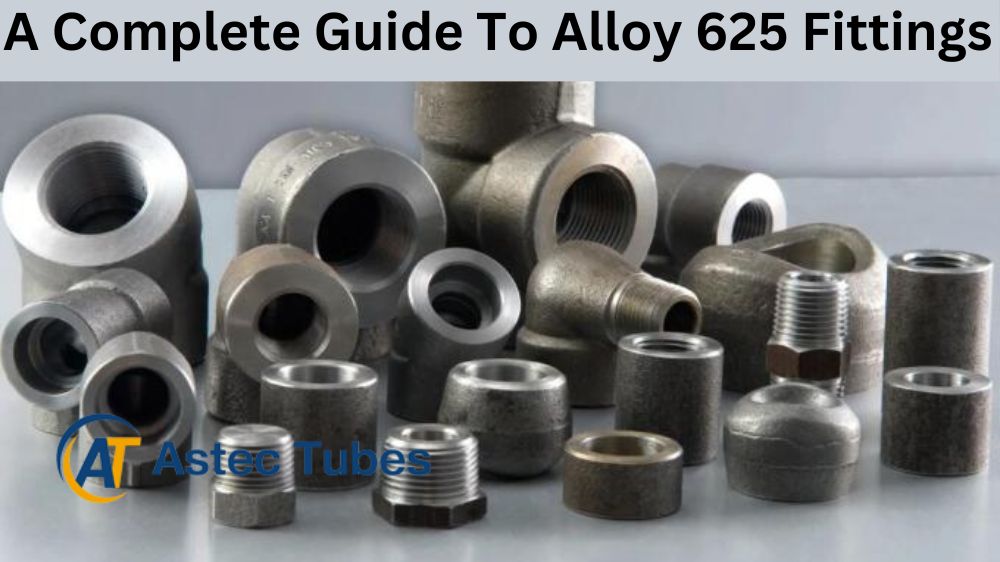

Alloy 625 fittings are piping components made of alloy 625, including elbows, tees, reducers, and so on, designed to join and change the direction or diameter of pipes. Alloy 625 fittings are used in the industry to connect pipes and control fluid flow in piping systems. They can be fabricated using various methods like welding, brazing, and machining.

Features Of Alloy 625 Fittings

Alloy 625 fittings offer excellent resistance to corrosion and heat, making them ideal for use in harsh environments. They are durable, with high strength and toughness, even at high temperatures. They are also easy to work with, thanks to their high machinability and weldability.

Applications Of Alloy 625 Fittings

Alloy 625 fittings are used in various industries, such as chemical processing, aerospace, marine engineering, power generation, and oil and gas exploration. In chemical processing, alloy 625 fittings are used in manufacturing processes involving corrosive chemicals like acids and alkalis, while in marine engineering, they are used in offshore drilling rigs and submarines. In aerospace, alloy 625 fittings are used to manufacture aircraft engines, and in power generation, they are used in gas turbines and heat exchangers.

Choosing The Right Alloy 625 Fitting

When choosing alloy 625 fittings for your application, it is essential to consider factors like size, pressure, and use environment to ensure proper functionality. You should also consult a professional to determine the best fitting type and fabrication method for your needs.

Maintenance Of Alloy 625 fittings

Maintaining alloy 625 fittings involves regular inspection and cleaning to prevent corrosion or damage. You should follow the manufacturer’s instructions for maintenance for better performance.

Conclusion

Alloy 625 fittings are essential piping components used in various industries due to their excellent properties, resistance to corrosion and heat, and high machinability. When choosing alloy 625 fittings for your specific application, it is essential to consider factors like size, pressure, and use environment to ensure proper functionality. Remember to consult a professional when selecting the fitting type and fabrication method. Proper maintenance is also required for better performance. We hope this guide provides the necessary information about alloy 625 fittings.